Kakaretso: Molao-motheo oa ho hokahanya, ho arola, ho theha, ts'ebetso le lisebelisoa tsa thepa ea ho sireletsa polyethylene e hokahaneng le silane bakeng sa terata le thapo li hlalositsoe ka bokhutšoanyane, 'me litšobotsi tse ling tsa thepa ea ho sireletsa polyethylene e hokahaneng le silane ka tlhaho ts'ebelisong le ts'ebelisong hammoho le lintlha tse amang boemo ba ho hokahanya ba thepa lia hlahisoa.

Mantsoe a bohlokoa: Ho hokahanya ha Silane; Ho hokahanya ha tlhaho; Polyethylene; Ho thibela ho ruruha; Terata le thapo

Thepa ea thapo ea polyethylene e hokahaneng le silane joale e sebelisoa haholo indastering ea terata le thapo e le thepa e sireletsang mocheso bakeng sa lithapo tsa motlakase tse nang le motlakase o tlase. Thepa e sebelisoang tlhahisong ea terata le thapo tse hokahaneng le motlakase tse nang le motlakase o tlase, le peroxide cross-linking le mahlaseli a kotsi ha e bapisoa le lisebelisoa tsa tlhahiso tse hlokahalang e bonolo, e bonolo ho e sebelisa, e theko e tlase e felletseng le melemo e meng, e fetohile thepa e etellang pele bakeng sa thapo e hokahaneng le motlakase o tlase e nang le insulation.

1. Molao-motheo oa ho hokahanya thepa ea cable e hokahaneng ka sefapano sa Silane

Ho na le mekhoa e 'meli e meholo e amehang ho etseng polyethylene e hokahaneng ka silane: ho hokela le ho hokela ka sefapano. Ts'ebetsong ea ho hokela, polymer e lahleheloa ke athomo ea eona ea H holim'a athomo ea khabone ea tertiary tlas'a ts'ebetso ea free initiator le pyrolysis ho ba li-free radicals, tse arabelang le sehlopha sa – CH = CH2 sa vinyl silane ho hlahisa polymer e hokahaneng e nang le sehlopha sa trioxysilyl ester. Ts'ebetsong ea ho hokela ka sefapano, polymer ea ho hokela e qala ka ho hydrolyzed ha ho na le metsi ho hlahisa silanol, 'me – OH e kopana le sehlopha se haufi sa Si-OH ho theha tlamo ea Si-O-Si, ka hona e hokahanya li-macromolecule tsa polymer.

2.Thepa ea cable e hokahaneng le sefapano sa Silane le mokhoa oa eona oa tlhahiso ea cable

Jwalo ka ha o tseba, ho na le mekgwa ya tlhahiso ya mehato e mmedi le e le nngwe bakeng sa dikhoele tse hokahantsweng ka silane le dikhoele tsa tsona. Phapang pakeng tsa mokgwa wa mehato e mmedi le mokgwa wa mohato o le mong e itshetlehile moo tshebetso ya ho kenya silane e etswang teng, tshebetso ya ho kenya ho moetsi wa thepa ya dikhoele bakeng sa mokgwa wa mehato e mmedi, tshebetso ya ho kenya fekthering ya tlhahiso ya dikhoele bakeng sa mokgwa wa mohato o le mong. Thepa ya ho kenya polyethylene e hokahantsweng ka silane e nang le karolo e kgolo ka ho fetisisa ya mmaraka e bopilwe ka thepa e bitswang A le B, mme thepa ya A e le polyethylene e hoketsweng ka silane le thepa ya B e le sehlopha se seholo sa catalyst. Karolo e ka hare ya ho kenya e hokahantswe ka metsing a futhumetseng kapa mouoane.

Ho na le mofuta o mong oa sesebelisoa sa ho thibela polyethylene se kopantsoeng ka silane sa mehato e 'meli, moo thepa ea A e hlahisoang ka tsela e fapaneng, ka ho kenya silane ea vinyl ka ho toba ka har'a polyethylene nakong ea tlhahiso ho fumana polyethylene ka liketane tse nang le makala a silane.

Mokhoa oa mohato o le mong o boetse o na le mefuta e 'meli, mokhoa oa setso oa mohato o le mong ke mefuta e fapaneng ea thepa e tala ho latela mokhoa oa karolelano ea sistimi e khethehileng ea ho lekanya ka nepo, ho ea ho extruder e khethehileng e entsoeng ka mokhoa o khethehileng mohatong o le mong ho phethela ho kenngoa le ho ntšoa ha setsi sa ho thibela likhoele tsa cable, ts'ebetsong ena, ha ho na granulation, ha ho hlokahale hore semela sa thepa ea cable se kenelle, ke fektheri ea cable ho phethela e le mong. Theknoloji ena ea tlhahiso ea likhoele tsa silane e hokahaneng le sefapano sa silane e kenngoang ka ho feletseng e tsoa linaheng tse ling 'me e theko e boima.

Mofuta o mong oa thepa ea ho thibela polyethylene e kopantsoeng ka silane e le 'ngoe e hlahisoa ke bahlahisi ba thepa ea cable, ke thepa eohle e tala ho latela mokhoa o itseng ka karolelano ea mokhoa o khethehileng oa ho kopanya, ho paka le ho rekisa, ha ho na thepa ea A le B, semela sa cable se ka ba ka ho toba ka har'a extruder ho phethela mohato ka nako e le 'ngoe ho kenya le ho ntša setsi sa cable insulation. Tšobotsi e ikhethang ea mokhoa ona ke hore ha ho hlokahale li-extruder tse khethehileng tse turang, kaha ts'ebetso ea ho kenya silane e ka phethoa ka extruder e tloaelehileng ea PVC, 'me mokhoa oa mehato e' meli o felisa tlhoko ea ho kopanya thepa ea A le B pele ho extrusion.

3. Sebopeho sa tlhahiso

Sebopeho sa thepa ea cable ea polyethylene e hokahaneng le silane ka kakaretso se entsoe ka resin ea thepa ea motheo, moqali, silane, antioxidant, inhibitor ea polymerization, catalyst, jj.

(1) Resin ea motheo hangata ke resin ea polyethylene e nang le density e tlase (LDPE) e nang le index ea ho qhibiliha (MI) ea 2, empa haufinyane tjena, ka nts'etsopele ea theknoloji ea resin ea maiketsetso le likhatello tsa litšenyehelo, polyethylene e nang le density e tlase (LLDPE) le eona e sebelisitsoe kapa e sebelisitsoe ka karolo e itseng e le resin ea motheo bakeng sa thepa ena. Resin tse fapaneng hangata li na le tšusumetso e kholo ho hokelleng le ho hokela ka lebaka la liphapang sebopehong sa tsona sa ka hare sa macromolecular, kahoo sebopeho se tla fetoloa ka ho sebelisa resin tse fapaneng tsa motheo kapa mofuta o tšoanang oa resin ho tsoa ho bahlahisi ba fapaneng.

(2) Sesebelisoa se sebelisoang haholo ke diisopropyl peroxide (DCP), senotlolo ke ho utloisisa boholo ba bothata, ha bo bongata haholo ho baka ho kenngoa ha silane ha boa lekana; bo bongata haholo ho baka ho hokahanya ha polyethylene, e leng se fokotsang ho phalla ha eona, bokaholimo ba motsoako o kentsoeng bo bataletse, ho thata ho hatella sistimi. Kaha bongata ba sesebelisoa se ekelitsoeng bo nyane haholo ebile boa utloahala, ho bohlokoa ho se hasanya ka ho lekana, kahoo hangata se eketsoa hammoho le silane.

(3) Silane hangata e sebelisoa silane e sa tlalang ea vinyl, ho kenyeletsoa vinyl trimethoxysilane (A2171) le vinyl triethoxysilane (A2151), ka lebaka la sekhahla se potlakileng sa hydrolysis sa A2171, kahoo khetha batho ba bangata ba A2171. Ka mokhoa o ts'oanang, ho na le bothata ba ho eketsa silane, bahlahisi ba thepa ea cable ba hajoale ba leka ho fihlela moeli oa bona o tlase ho fokotsa litšenyehelo, hobane silane e kentsoe kantle ho naha, theko e theko e boima haholo.

(4) Anti-oxidant ke ho netefatsa botsitso ba ts'ebetso ea polyethylene le ho thibela botsofali ka cable le ho eketsa, anti-oxidant ts'ebetsong ea ho kenya silane e na le karolo ea ho thibela karabelo ea ho kenya, kahoo ts'ebetso ea ho kenya, ho eketsoa ha anti-oxidant ho lokela ho ba hlokolosi, bongata bo ekelitsoeng ho nahana ka bongata ba DCP ho tsamaisana le khetho. Ts'ebetsong ea ho kopanya mekhahlelo e 'meli, boholo ba antioxidant bo ka eketsoa sehlopheng sa catalyst master, e leng se ka fokotsang tšusumetso ts'ebetsong ea ho kenya. Ts'ebetsong ea ho kopanya mohato o le mong, antioxidant e teng ts'ebetsong eohle ea ho kenya, kahoo khetho ea mefuta le bongata bo bohlokoa haholo. Li-antioxidants tse sebelisoang hangata ke 1010, 168, 330, jj.

(5) Mothibi oa polymerization o eketsoa e le ho thibela ho kenngoa ha li-graft le ts'ebetso ea ho hokahanya ha li-side reactions tse etsahalang, ts'ebetsong ea ho kopanya ho eketsa moemeli oa anti-cross-linking, ho ka fokotsa ka katleho ketsahalo ea ho kopana ha C2C, ka hona ho ntlafatsa mokelikeli oa ts'ebetso, ho phaella moo, ho eketsoa ha graft maemong a tšoanang ho tla etelloa pele ke hydrolysis ea silane holim'a mothibi oa polymerization ho ka fokotsa hydrolysis ea polyethylene e kopantsoeng, ho ntlafatsa botsitso ba nako e telele ba thepa ea graft.

(6) Hangata di-catalyst ke di-derivative tsa organotin (ntle le ho kopanya ha tlhaho), tse atileng haholo ke dibutyltin dilaurate (DBDTL), eo hangata e eketsoang ka sebopeho sa masterbatch. Ts'ebetsong ya mehato e mmedi, graft (thepa ya A) le catalyst master batch (thepa ya B) di pakwa ka thoko mme thepa ya A le B di kopanngwa mmoho pele di eketswa ho extruder ho thibela ho kopanya pele ho tshekatsheko ya thepa ya A. Tabeng ya di-insulation tsa polyethylene tse hokahantsweng ka silane ya mohato o le mong, polyethylene e ka hara sephutheloana ha e so kenngwe, kahoo ha ho na bothata ba ho kopanya pele ho tshekatsheko mme ka hona catalyst ha e hloke ho pakwa ka thoko.

Ho phaella moo, ho na le di-silane tse kopantsweng tse fumanehang mmarakeng, e leng motswako wa silane, moqali, antioxidant, ditlolo tse ding le di-anti-copper agents, mme hangata di sebediswa mekgweng ya ho hokahanya di-silane ka mohato o le mong dimeleng tsa di-cable.

Ka hona, tlhahiso ea silane cross-linked polyethylene insulation, eo motsoako oa eona o sa nkiloeng o le thata haholo 'me o fumaneha tlhahisoleseling e amehang, empa tlhahiso e nepahetseng ea tlhahiso, e itšetlehile ka liphetoho tse ling e le hore e phetheloe, e hlokang kutloisiso e felletseng ea karolo ea likarolo tlhahisong le molao oa tšusumetso ea tsona ts'ebetsong le tšusumetso ea tsona e kopanetsoeng.

Mefuteng e mengata ea thepa ea cable, thepa ea cable e hokahaneng ka silane (ebang ke ea mehato e 'meli kapa ea mohato o le mong) e nkoa e le eona feela mefuta e fapaneng ea lits'ebetso tsa lik'hemik'hale tse etsahalang ho extrusion, mefuta e meng e kang thepa ea cable ea polyvinyl chloride (PVC) le thepa ea cable ea polyethylene (PE), ts'ebetso ea granulation ea extrusion ke ts'ebetso ea 'mele ea ho kopanya, leha e le hore thepa ea cable e hokahaneng ka lik'hemik'hale le mahlaseli a ho bonesa, ebang ke ts'ebetsong ea granulation ea extrusion, kapa sistimi ea extrusion Cable, ha ho na ts'ebetso ea lik'hemik'hale e etsahalang, kahoo, ha ho bapisoa, tlhahiso ea thepa ea cable e hokahaneng ka silane le extrusion ea insulation ea cable, taolo ea ts'ebetso e bohlokoa haholo.

4. Ts'ebetso ea tlhahiso ea ho kenya polasetiki ea silane e hokahaneng le cross-linked polyethylene e nang le mehato e 'meli

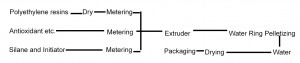

Ts'ebetso ea tlhahiso ea thepa ea silane e kopantsoeng ka cross-linked polyethylene A e ka emeloa ka bokhutšoanyane ke Setšoantšo sa 1.

Setšoantšo sa 1 Ts'ebetso ea tlhahiso ea thepa ea ho thibela polyethylene e kopantsoeng ka silane ea mehato e 'meli A

Lintlha tse ling tsa bohlokoa ts'ebetsong ea tlhahiso ea ho kenya polasetiki ea polyethylene e hokahaneng le silane ea mehato e 'meli:

(1) Ho omisa. Kaha resin ea polyethylene e na le metsi a manyane, ha e ntšoa mochesong o phahameng, metsi a arabela ka potlako le lihlopha tsa silyl ho hlahisa ho kopanya, e leng se fokotsang ho phalla ha ho qhibiliha le ho hlahisa ho kopanya pele ho ho kopanya. Thepa e felileng e boetse e na le metsi kamora ho phola ha metsi, e leng se ka boela sa baka ho kopanya pele ho ho kopanya haeba e sa tlosoe, 'me e tlameha ho omisoa. E le ho netefatsa boleng ba ho omisa, ho sebelisoa yuniti ea ho omisa e tebileng.

(2) Ho lekanya. Kaha ho nepahala ha sebopeho sa thepa ho bohlokoa, sekala sa ho bekha sa tahlehelo-ka-boima se kentsweng kantle ho naha hangata se sebediswa. Resin ya polyethylene le antioxidant di lekanngwa mme di fepuwa ka koung ya phepelo ya extruder, ha silane le initiator di kenngwa ka pompo ya thepa ya metsi ka hara barele ya bobedi kapa ya boraro ya extruder.

(3) Ho kenya dikotwana ka ho ntsha. Ts'ebetso ya ho kenya dikotwana ka silane e phethelwa ka hara extruder. Ditlhophiso tsa tshebetso ya extruder, ho kenyeletswa mocheso, motswako wa dikotwana, lebelo la dikotwana le sekgahla sa ho fepa, di tlameha ho latela molao-motheo wa hore thepa e karolong ya pele ya extruder e ka qhibilihiswa ka botlalo mme ya kopanngwa ka ho lekana, ha ho sa lakatsehe ho bola pele ho nako ha peroxide, le hore thepa e tshwanang ka botlalo karolong ya bobedi ya extruder e tlameha ho bola ka botlalo mme tshebetso ya ho kenya dikotwana e phethetswe. Dithempereichara tse tlwaelehileng tsa karolo ya extruder (LDPE) di bontshitswe ho Tafole ya 1.

Tafole ea 1 Thempereichara ea libaka tsa extruder tse nang le mehato e 'meli

| Sebaka sa ho sebetsa | Sebaka sa 1 | Sebaka sa 2 | Sebaka sa 3 ① | Sebaka sa 4 | Sebaka sa 5 |

| Thempereichara P °C | 140 | 145 | 120 | 160 | 170 |

| Sebaka sa ho sebetsa | Sebaka sa 6 | Sebaka sa 7 | Sebaka sa 8 | Sebaka sa 9 | Molomo o shoa |

| Thempereichara °C | 180 | 190 | 195 | 205 | 195 |

① ke moo silane e eketsoang teng.

Lebelo la sekerefo sa extruder le etsa qeto ea nako ea bolulo le phello ea ho kopanya thepa e ka har'a extruder, haeba nako ea bolulo e le khutšoanyane, ho bola ha peroxide ha hoa fella; haeba nako ea bolulo e le telele haholo, viscosity ea thepa e ntšitsoeng e ea eketseha. Ka kakaretso, nako e tloaelehileng ea bolulo ea granule ho extruder e lokela ho laoloa nakong ea ho bola ha halofo ea bophelo ba qalong ea makhetlo a 5-10. Lebelo la ho fepa ha le na tšusumetso e itseng feela nakong ea bolulo ea thepa, empa hape le ho kopanyeng le ho kuta thepa, ho khetha lebelo le loketseng la ho fepa le hona ho bohlokoa haholo.

(4) Sephutheloana. Thepa ea ho thibela mocheso e hokahaneng le silane ea mehato e 'meli e lokela ho pakoa ka mekotleng ea aluminium-plastiki e kopaneng moeeng o tobileng ho felisa mongobo.

5. Ts'ebetso ea tlhahiso ea thepa ea polyethylene e hokahaneng le silane e le 'ngoe e nang le litšepe tse tšekaletseng

Thepa ea ho kenya polasetiki e kopantsoeng le silane e nang le mohato o le mong ka lebaka la ts'ebetso ea eona ea ho kenya polasetiki e hoketsoe fekthering ea cable ea mantlha ea ho kenya polasetiki, kahoo mocheso oa ho kenya polasetiki o phahame haholo ho feta mokhoa oa mehato e 'meli. Le hoja mokhoa oa ho kenya polasetiki o kopantsoeng le silane o kopantsoeng le oona o se o nahanisisitsoe ka botlalo ka ho hasana ka potlako ha seqapi le silane le thepa, empa ts'ebetso ea ho kenya polasetiki e tlameha ho netefatsoa ke mocheso, e leng semela sa tlhahiso ea polyethylene e kopantsoeng le silane e nang le mohato o le mong se hatelletse bohlokoa ba khetho e nepahetseng ea mocheso oa ho ntša, mocheso o khothaletsoang ka kakaretso oa ho ntša o bontšitsoe ho Tafole ea 2.

Tafole ea 2 Mocheso oa extruder oa mohato o le mong oa sebaka ka seng (yuniti: ℃)

| Sebaka | Sebaka sa 1 | Sebaka sa 2 | Sebaka sa 3 | Sebaka sa 4 | Sekoahelo | Hlooho |

| Thempereichara | 160 | 190 | 200~210 | 220~230 | 230 | 230 |

Ena ke e 'ngoe ea mefokolo ea ts'ebetso ea polyethylene e hokahaneng le silane ea mohato o le mong, eo hangata e sa hlokeheng ha ho ntšoa likhoele ka mehato e 'meli.

6. Lisebelisoa tsa tlhahiso

Lisebelisoa tsa tlhahiso ke tiisetso ea bohlokoa ea taolo ea ts'ebetso. Tlhahiso ea likhoele tse hokahaneng tsa silane e hloka tekanyo e phahameng haholo ea ho nepahala ha taolo ea ts'ebetso, kahoo khetho ea lisebelisoa tsa tlhahiso e bohlokoa haholo.

Tlhahiso ea thepa ea ho thibela polyethylene e kopantsoeng ka silane ea mehato e 'meli. Sesebelisoa sa tlhahiso ea thepa, se sebelisoang haholo malapeng ho feta se nang le li-extruder tse peli tse tšoanang le tsa isotropic tse nang le boima bo sa keneng ka ntle, lisebelisoa tse joalo li ka fihlela litlhoko tsa ho nepahala ha taolo ea ts'ebetso, khetho ea bolelele le bophara ba extruder e nang le li-extruder tse peli ho netefatsa hore thepa e lula nako, khetho ea boima bo sa keneng ka ntle ho naha ho netefatsa ho nepahala ha metsoako. Ehlile ho na le lintlha tse ngata tsa lisebelisoa tse hlokang ho fuoa tlhokomelo e felletseng.

Jwalo ka ha ho boletswe pejana, disebediswa tsa tlhahiso ya dikheibole tse hokahantsweng ka mohato o le mong tsa silane fekthering ya dikheibole di kenngwa kantle ho naha, di bitsa tjhelete e ngata, bahlahisi ba disebediswa tsa lapeng ha ba na disebediswa tse tshwanang tsa tlhahiso, lebaka ke ho hloka tshebedisano-mmoho pakeng tsa bahlahisi ba disebediswa le bafuputsi ba diforomo le ditsamaiso.

7.Silane tlhaho e hokahaneng le polyethylene e sireletsang lintho tse hokahaneng

Thepa ea ho thibela polyethylene e hokahaneng le tlhaho ea Silane e ntlafalitsoeng lilemong tsa morao tjena e ka hokahanngoa tlas'a maemo a tlhaho ka matsatsi a 'maloa, ntle le ho qoelisoa ka mouoane kapa ka metsing a futhumetseng. Ha e bapisoa le mokhoa oa setso oa ho hokahanya silane, thepa ena e ka fokotsa ts'ebetso ea tlhahiso bakeng sa bahlahisi ba lithapo, ea fokotsa litšenyehelo tsa tlhahiso le ho eketsa bokhoni ba tlhahiso. Ho sireletsa polyethylene e hokahaneng le tlhaho ea Silane ho ntse ho ananeloa le ho sebelisoa ke bahlahisi ba lithapo.

Lilemong tsa morao tjena, ho sireletsa polasetiki ea silane ea tlhaho e hokahaneng le polyethylene ea lapeng ho se ho holile 'me ho hlahisitsoe ka bongata bo boholo, ka melemo e itseng ka theko ha e bapisoa le thepa e tsoang linaheng tse ling.

7. 1 Mehopolo ea ho etsa li-insulation tsa polyethylene tse hokahaneng ka tlhaho tsa silane

Li-insulation tsa polyethylene tse hokahaneng le tlhaho tsa Silane li hlahisoa ka mokhoa oa mehato e 'meli, ka mokhoa o tšoanang o nang le resin ea motheo, moqali, silane, antioxidant, polymerisation inhibitor le catalyst. Mokhoa oa ho kopanya li-insulators tsa polyethylene tse hokahaneng le tlhaho tsa silane o ipapisitse le ho eketsa sekhahla sa ho kopanya silane sa thepa ea A le ho khetha catalyst e sebetsang hantle ho feta li-insulators tsa polyethylene tse hokahaneng le metsi a futhumetseng a silane. Tšebeliso ea thepa ea A e nang le sekhahla se phahameng sa ho kopanya silane hammoho le catalyst e sebetsang hantle e tla nolofalletsa insulator ea polyethylene e hokahaneng le silane ho kopanya kapele esita le mochesong o tlase le ka mongobo o sa lekaneng.

Lisebelisoa tsa A bakeng sa li-insulator tsa polyethylene tse kopantsoeng ka tlhaho tsa silane tse tsoang kantle li hlahisoa ka copolymerisation, moo litaba tsa silane li ka laoloang boemong bo phahameng, athe tlhahiso ea lisebelisoa tsa A tse nang le sekhahla se phahameng sa ho kopanya ka ho kopanya silane e thata. Resin ea motheo, moqali le silane tse sebelisitsoeng risepeng li lokela ho fetoloa le ho fetoloa ho latela mefuta le ho eketsa.

Khetho ea resist le tokiso ea tekanyo ea eona le tsona li bohlokoa, kaha keketseho ea sekhahla sa ho kopanya silane e lebisa ho likarabelo tse ling tsa lehlakore la CC crosslinking. E le ho ntlafatsa ho phalla ha ts'ebetso le boemo ba bokaholimo ba thepa ea A bakeng sa ho ntša cable ka mor'a moo, ho hlokahala tekanyo e loketseng ea polymerization inhibitor ho thibela ka katleho CC crosslinking le pele ho crosslinking.

Ho phaella moo, di-catalyst di bapala karolo ya bohlokwa ho eketseng sekgahla sa ho hokahanya mme di lokela ho kgethwa e le di-catalyst tse sebetsang hantle tse nang le dielemente tse se nang tshepe tse fetohang.

7. 2 Nako ea ho hokahanya ea silane e hokahaneng ka tlhaho le li-insulation tsa polyethylene tse hokahaneng ka tlhaho

Nako e hlokahalang ho phethela ho hokahanya ha silane natural cross-linked polyethylene insulation boemong ba yona ba tlhaho e itshetlehile ka mocheso, mongobo le botenya ba lera la insulation. Ha mocheso le mongobo di le hodimo, botenya ba lera la insulation bo ntse bo fokola, nako ya ho hokahanya e kgutshwane, mme nako e telele e fapaneng e ba telele. Kaha mocheso le mongobo di fapana ho ya ka sebaka le ho tloha sehleng se seng ho ya ho se seng, esita le sebakeng se le seng le ka nako e le nngwe, mocheso le mongobo kajeno le hosane di tla fapana. Ka hona, nakong ya tshebediso ya thepa, mosebedisi o lokela ho fumana nako ya ho hokahanya ho ya ka mocheso le mongobo wa lehae le o teng, hammoho le tlhaloso ya thapo le botenya ba lera la insulation.

Nako ea poso: Phato-13-2022