Lithapo tse hanelang mocheso o phahameng li bolela lithapo tse khethehileng tse ka bolokang ts'ebetso e tsitsitseng ea motlakase le ea mechini libakeng tse nang le mocheso o phahameng. Li sebelisoa haholo lifofaneng, lifofaneng, peteroleng, ho qhibilihisa tšepe, matla a macha, indastering ea sesole le mafapheng a mang.

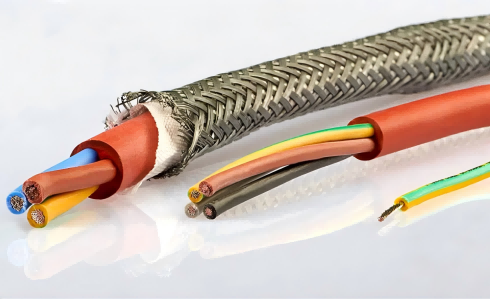

Lisebelisoa tse tala tsa likhoele tse hanelang mocheso o phahameng li kenyelletsa haholo-holo thepa ea conductor, thepa ea ho thibela mocheso, le thepa ea ho thibela mocheso. Har'a tsona, conductor e lokela ho ba le conductivity e ntle le khanyetso ea mocheso o phahameng; lera la insulation le hloka ho ba le litšobotsi tse kang khanyetso ea mocheso o phahameng, khanyetso ea ho tsofala, le khanyetso ea k'hemik'hale ea ho bola; sheath e lokela ho ba le mesebetsi e kang khanyetso ea mocheso o phahameng, khanyetso ea botsofali, khanyetso ea oli le ts'ireletso ea mechini.

Ka kakaretso, mokhanni oa likhoele tse hanelang mocheso o phahameng o entsoe ka koporo kapa aluminium, e huloang ka har'a lithapo tsa bophara bo fapaneng ka mochini oa ho hula terata. Nakong ea ts'ebetso ea ho hula, liparamente tse kang lebelo la ho hula, mocheso oa hlobo, le mocheso oa sehatsetsing li tlameha ho laoloa ka thata ho netefatsa hore bokaholimo bo boreleli le thepa ea mechini ea lithapo li fihlela litlhoko.

Lera la ho kenya mocheso ke karolo ea bohlokoa ea likhoele tse hanelang mocheso o phahameng, 'me mokhoa oa ho lokisa oa lona o ama ka ho toba ts'ebetso eohle ea khoele. Lisebelisoa tsa polymer tse kang polytetrafluoroethylene (PTFE), fluorinated ethylene propylene (FEP), polyether ether ketone (PEEK), kapa rabara ea silicone ea ceramic hangata li sebelisoa ho theha lera la ho kenya mocheso ka mekhoa ea ho ntša kapa ea ho bopa. Nakong ea ts'ebetso ena, mocheso, khatello le lebelo la mohala oa tlhahiso li tlameha ho laoloa ka nepo ho netefatsa hore lera la ho kenya mocheso le na le botenya bo lekanang, ha le na liphoso, le ts'ebetso e tsitsitseng ea ho kenya mocheso ka motlakase.

Sekotjana se sebetsa e le lera le ka ntle la tšireletso la thapo, haholo-holo le sebelisetsoang ho sireletsa khahlanong le tšenyo ea mechini le khoholeho e matla ea tikoloho. Lisebelisoa tse tloaelehileng tsa ho koahela li kenyelletsa polyvinyl chloride (PVC), polyethylene (PE),polyethylene e hokahaneng ka sefapano (XLPE), le di-fluoroplastic tse ikgethang. Nakong ya tshebetso ya ho bopa extrusion, mocheso wa extrusion, kgatello ya hlooho, le lebelo la ho hula di lokela ho laolwa ka thata ho netefatsa hore sheath e teteaneng, e teteaneng ka ho lekana, mme e na le ponahalo e boreledi.

Lintlha tsa bohlokoa tse latelang li lokela ho laoloa ka thata nakong ea ts'ebetso ea tlhahiso ho netefatsa boleng ba thapo e felileng:

1. Taolo ea Mocheso: Mocheso o tlameha ho laoloa ka nepo mohatong o mong le o mong oa ts'ebetso ho netefatsa ts'ebetso ea thepa le botsitso ba ts'ebetso.

2. Taolo ea Khatello: Khatello e tlameha ho laoloa ka mokhoa o utloahalang nakong ea ho ntša kapa ho bopa ho netefatsa botenya le boleng ba insulation le sheath.

3. Taolo ea Lebelo: Lebelo la terata le tlameha ho laoloa ka thata nakong ea lits'ebetso tse kang ho hula le ho ntša ho netefatsa katleho ea tlhahiso le botsitso ba sehlahisoa.

4. Kalafo ea ho Omisa: Lisebelisoa tse ling tsa polymer li hloka ho omisoa pele ho nako ho qoba liphoso tse kang lipululana nakong ea ts'ebetso.

5. Tlhahlobo ea Boleng: Litlhahlobo tse tiileng li tlameha ho etsoa nakong ea ts'ebetso ea tlhahiso le ha sehlahisoa se phethetsoe, ho kenyeletsoa tlhahlobo ea ponahalo, tekanyo ea boholo, liteko tsa ts'ebetso ea motlakase, le liteko tsa botsofali ba mocheso o phahameng, ho netefatsa hore sehlahisoa se fihlela maemo le litlhoko tsa ts'ebeliso.

Tlhahiso ea likhoele tse hanelang mocheso o phahameng e kenyelletsa mehato e mengata e nepahetseng, 'me taolo ea boleng bo felletseng e tlameha ho kenngoa tšebetsong ho fumana lihlahisoa tse tšoanelehang. Ka ho tseba ka botlalo khetho ea thepa e tala, phetoho ea liparamente tsa ts'ebetso, le tsamaiso ea ts'ebetso ea tlhahiso, katleho ea tlhahiso le botsitso ba lihlahisoa tsa likhoele li ka ntlafatsoa haholo. Ho feta moo, ho khothaletsa boqapi ba theknoloji le ntlafatso ea lisebelisoa, ho hlahisa mela ea tlhahiso e iketsang le litsamaiso tse bohlale tsa ho lemoha, ho tla ntlafatsa boleng ba tlhahiso le tlholisano ea indasteri, ho bula menyetla e pharaletseng ea nts'etsopele bakeng sa tlhahiso ea likhoele tse hanelang mocheso o phahameng.

Jwalo ka mofani wa thepa ya cable ya profeshenale,LEFATŠE LE LE LENGKamehla e ikemiselitse ho fa bareki ba lefats'e ka bophara litharollo tse felletseng tsa thepa ea cable tsa boleng bo holimo. Sistimi ea lihlahisoa ea k'hamphani e kenyelletsa thepa e khethehileng e boletsoeng sehloohong sena, joalo ka polyvinyl chloride (PVC), polyethylene e kopantsoeng ka sefapano (XLPE), polytetrafluoroethylene (PTFE), hammoho le litheipi tse sebetsang hantle joalo ka Mylar Tape, Water Blocking Tape, le Semi-conductive Water Blocking Tape, le thepa ea cable ea optical ea maemo a holimo joalo ka PBT, FRP, le Aramid Yarn. Re khomarela boqapi ba theknoloji joalo ka enjene ea nts'etsopele, re ntlafatsa mekhoa ea thepa le lits'ebetso tsa tlhahiso khafetsa ho fa bareki mefuta e felletseng ea lihlahisoa tse nang le ts'ebetso e ntle le boleng bo tsitsitseng, re thusa likhoebo tsa tlhahiso ea cable ho ntlafatsa tlholisano ea lihlahisoa le ho khothaletsa tsoelo-pele ea theknoloji le nts'etsopele e ncha ea indasteri ea cable.

Nako ea poso: Loetse-19-2025