Polybutylene terephthalate(PBT) ke polyester e tletseng thermoplastic e semi-crystalline, eo hangata e leng tšoeu joaloka lebese, e tiileng ka granular mochesong oa kamore, e sebelisoa hangata tlhahisong ea thepa ea thermoplastic ea secondary coating ea cable ea optical.

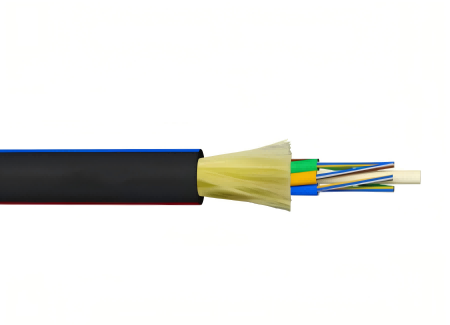

Ho koahela ka bobeli ha faeba ya optical ke ts'ebetso ea bohlokoa haholo tlhahisong ea faeba ya optical. Ha re bua ka bonolo, ho eketsa lera le sireletsang ho sekoahelo sa mantlha sa faeba ya optical kapa lera la buffer ho ka ntlafatsa bokhoni ba faeba ya optical ho hanela khatello ea longitudinal le radial le ho nolofatsa ts'ebetso ea fiber ea optical ka mor'a ho sebetsa. Hobane thepa ea ho koahela e haufi le faeba ea optical, e na le tšusumetso e kholo ts'ebetsong ea faeba ea optical, kahoo thepa ea ho koahela e hlokahala hore e be le coefficient e nyane ea katoloso e otlolohileng, kristale e phahameng kamora ho tsoa, botsitso bo botle ba lik'hemik'hale le mocheso, mabota a boreleli a ka hare le a ka ntle a lera la ho koahela, matla a itseng a ho tensile le modulus ea Young, 'me e na le ts'ebetso e ntle ea ts'ebetso. Ho koahela ka faeba ka kakaretso ho arotsoe ka mekhahlelo e 'meli: sekoahelo se hlephileng le sekoahelo se tiileng. Har'a tsona, thepa ea sheath e hlephileng e sebelisoang sekoahelong sa sheath e hlephileng ke lera la bobeli la ho koahela le hlephileng le ntšelitsoeng boemong ba sleeve e hlephileng ka ntle ho fiber ea mantlha ea ho koahela.

PBT ke thepa e tloaelehileng e hlephileng e nang le thepa e ntle ea ho etsa le ho sebetsana le eona, e monyang mongobo o tlase le ts'ebetso e theko e phahameng. E sebelisoa haholo-holo hoPBTphetoho, ho taka terata ya PBT, casing, ho taka filimi le masimo a mang. PBT e na le thepa e ntle ya mechini (jwalo ka ho hanyetsa ho tensile, ho hanyetsa ho kobeha, ho hanyetsa kgatello ya lehlakore), ho hanyetsa ho solvent hantle, ho hanyetsa oli, ho hanyetsa ho bola ha dikhemikhale, le ho tiisa ha faeba, ho tiisa ha thapo le dikarolo tse ding tsa thapo di tsamaisana hantle, mme di na le tshebetso e ntle ya ho sebetsana le ho bopa, ho monya mongobo o tlase, ho boloka tjhelete. Maemo a yona a mantlha a tshebetso ya botekgeniki a kenyeletsa: viscosity ya kahare, matla a tlhahiso, ho tiisa le ho kobeha ha modulus ya elastic, matla a tshusumetso (notch), coefficient ya katoloso e otlolohileng, ho monya metsi, ho hanyetsa hydrolysis le tse ding.

Leha ho le jwalo, ka phetoho ya sebopeho sa thapo ya faeba le tikoloho ya tshebetso, ditlhoko tse ding di etswa pele bakeng sa ho betla ha faeba. Ho kristale e phahameng, ho fokotseha ho tlase, coefficient e tlase ya katoloso ya mola o otlolohileng, ho tiya ho hoholo, matla a ho hatella a hodimo, ho hanyetsa dikhemikhale hantle, tshebetso e ntle ya ho sebetsana le dintho, le thepa e theko e tlase ke dipheo tse phehellwang ke bahlahisi ba thapo ya optical. Hona jwale, ho na le mefokolo tshebedisong le thekong ya tube ya beam e entsweng ka thepa ya PBT, mme dinaha tse ding di se di qadile ho sebedisa thepa ya alloy ya PBT ho nkela thepa e hlwekileng ya PBT sebaka, e leng se bapetseng phello le karolo e ntle. Hona jwale, dikhamphani tse mmalwa tse kgolo tsa thapo ya lehae di ntse di itokisa ka mafolofolo, dikhamphani tsa thepa ya thapo di hloka boqapi bo tswelang pele ba theknoloji, dipatlisiso le ntshetsopele ya thepa e ntjha.

Ehlile, indastering ka kakaretso ea PBT, lits'ebetso tsa cable ea fiber optic li nka karolo e nyane feela ea 'maraka oa PBT. Ho ea ka mehloli ea indasteri, indastering eohle ea PBT, boholo ba karolo ea 'maraka bo hapiloe haholo ke masimo a mabeli a likoloi le motlakase. Lihokelo, li-relay le lihlahisoa tse ling tse entsoeng ka thepa ea PBT e fetotsoeng li sebelisoa haholo lisebelisoa tsa likoloi, tsa elektroniki le tsa motlakase, lisebelisoa tsa mechini le masimo a mang, 'me esita le PBT e na le lits'ebetso tšimong ea masela, joalo ka li-bristles tsa borashe ba meno le tsona li entsoe ka PBT. Tse latelang ke lits'ebetso tse akaretsang tsa PBT masimong a fapaneng:

1. Masimo a elektroniki le a motlakase

Lisebelisoa tsa PBT li sebelisoa haholo masimong a elektroniki le a motlakase, joalo ka li-socket tsa motlakase, li-plug, li-socket tsa elektroniki le likarolo tse ling tsa motlakase tsa lapeng. Hobane thepa ea PBT e na le ts'ebetso e ntle ea ho thibela mocheso le ho hanyetsa mocheso o phahameng, e loketse haholo khetla, bracket, lakane ea ho thibela mocheso le likarolo tse ling tsa lisebelisoa tsa elektroniki le tsa motlakase. Ho phaella moo, lisebelisoa tsa PBT li ka boela tsa sebelisoa ho etsa sekoahelo se ka morao sa skrine sa LCD, khetla ea TV le tse ling.

2. Tšimo ea likoloi

Lisebelisoa tsa PBT le tsona li sebelisoa haholo lefapheng la likoloi. Ka lebaka la melemo ea tsona ea mocheso o phahameng, mafome le ho hanyetsa ho tsofala, lisebelisoa tsa PBT li sebelisoa haholo tlhahisong ea likarolo tsa likoloi, tse kang intake manifold, oil pump housing, sensor housing, likarolo tsa sistimi ea brake, jj. Ho phaella moo, lisebelisoa tsa PBT li ka boela tsa sebelisoa bakeng sa litulo tsa hlooho tsa likoloi, mekhoa ea ho lokisa litulo, jj.

3. Indasteri ea mechini

Indastering ea mechini, thepa ea PBT e atisa ho sebelisoa ho etsa li-handle tsa lisebelisoa, li-switch, likonopo, jj. Thepa ea PBT e na le matla a maholo a mechini le ho hanyetsa ho tsofala, e ka mamella matla a fapaneng a mechini, 'me e na le khanyetso e ntle ea k'hemik'hale ea ho bola, e loketseng likarolo tse fapaneng lefapheng la indasteri ea mechini.

4. Indasteri ea lisebelisoa tsa bongaka

Thepa ea PBT e na le khanyetso e ntle ea mocheso o phahameng le botsitso bo phahameng ba lik'hemik'hale, e leng se loketseng haholo tlhahiso ea lisebelisoa tsa bongaka. Mohlala, thepa ea PBT e ka sebelisoa ho etsa matlo a lisebelisoa tsa bongaka, liphaephe, lihokelo, jj. Ho phaella moo, thepa ea PBT e ka boela ea sebelisoa ho etsa lisirinji tsa bongaka, lisete tsa infusion le lisebelisoa tse fapaneng tsa phekolo.

5. Puisano ea mahlo

Lefapheng la puisano ea mahlo, PBT e sebelisoa haholo tlhahisong ea lithapo tsa mahlo e le thepa e tloaelehileng ea matsoho a hlephileng. Ho phaella moo, thepa ea PBT e sebelisoa haholo lisebelisoa tsa mahlo. Ka lebaka la thepa ea eona e ntle ea mahlo le ho hanyetsa mocheso o phahameng, thepa ea PBT e sebelisoa ho etsa lihokelo tsa fiber ea mahlo, liforeimi tsa kabo ea fiber ea mahlo, jj. Ho phaella moo, thepa ea PBT e ka boela ea sebelisoa ho etsa lilense, liipone, lifensetere le likarolo tse ling tsa mahlo.

Ho ya ka pono ya indasteri yohle, dilemong tsa morao tjena, dikgwebo tse amehang di ikemiseditse ho ntshetsa pele mefuta e fapaneng ya tshebediso ya mahlale a matjha le dihlahiswa tse ntjha, mme PBT e ntshetse pele ka tsela ya tshebetso e phahameng, tshebetso le mefuta e fapaneng. Matla a ho tensile a resin ya PBT e hlwekileng, matla a ho kobeha le modulus ya ho kobeha di tlase, di ke ke tsa sebediswa haholo tshimong ya diindasteri, kahoo bakeng sa ditlhoko tsa tshimo ya diindasteri, indasteri ka phetoho ho ntlafatsa tshebetso ya PBT. Mohlala, faeba ya khalase e eketswa ho PBT - faeba ya khalase e na le melemo ya ho sebediswa ka matla, tshebetso e bonolo ya ho tlatsa le ditjeo tse tlase. Ka ho eketsa faeba ya khalase ho PBT, melemo ya pele ya resin ya PBT e a sebediswa, mme matla a ho tensile, matla a ho kobeha le matla a ho ama a dihlahiswa tsa PBT di ntlafatswa haholo.

Hona jwale, mekgwa e meholo lapeng le kantle ho naha ke phetoho ya copolymerization, phetoho ya ho tlatsa thepa e sa pheleng, theknoloji ya nanocomposite, phetoho ya ho kopanya, jj., ho ntlafatsa tshebetso e felletseng ya PBT. Phetoho ya thepa ya PBT e shebane haholo le dikarolo tsa matla a phahameng, ho thibela malakabe a mangata, ho warpage e tlase, pula e tlase le dielectric e tlase.

Ka kakaretso, ha e le indastering yohle ya PBT, tlhoko ya tshebediso mafapheng a fapaneng e ntse e le kgolo haholo, mme diphetoho tse fapaneng ho ya ka tlhoko ya mmaraka le tsona ke dipheo tse tlwaelehileng tsa dipatlisiso le ntshetsopele tsa dikgwebo tsa indasteri ya PBT.

Nako ea poso: Tshitwe-17-2024