Tshebetso ya thepa e sireletsang mocheso e ama ka ho toba boleng, bokgoni ba ho sebetsana le dithapo le dikheibole. Tshebetso ya thepa e sireletsang mocheso e ama ka ho toba boleng, bokgoni ba ho sebetsana le dithapo le dikheibole.

Lithapo le likhoele tsa 1.PVC polyvinyl chloride

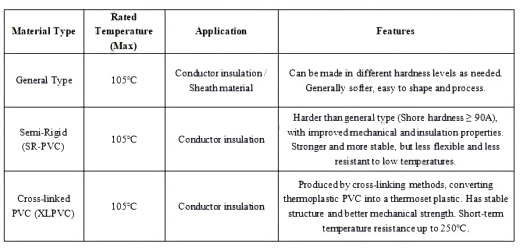

Polyvinyl chloride (eo ho tloha joale e tla bitsoaPVC) thepa ea ho thibela mocheso ke metsoako eo ho eona li-stabilizer, li-plasticizer, li-retant lashes, li-lubricant le lintho tse ling tse eketsoang phofo ea PVC. Ho ea ka lits'ebetso tse fapaneng le litlhoko tse ikhethang tsa lithapo le likhoele, foromo e fetoloa ka nepo. Kamora lilemo tse mashome tsa tlhahiso le ts'ebeliso, theknoloji ea tlhahiso le ts'ebetso ea PVC joale e se e holile haholo. Thepa ea ho thibela mocheso ea PVC e na le lits'ebetso tse pharaletseng haholo tšimong ea lithapo le likhoele 'me e na le litšobotsi tse ikhethang tsa eona:

A. Theknoloji ea tlhahiso e butsoitse, e bonolo ho e theha le ho e sebetsana. Ha e bapisoa le mefuta e meng ea thepa ea ho thibela likhoele, ha e na litšenyehelo tse tlase feela, empa hape e ka laola phapang ea 'mala ka katleho, ho benya, khatiso, katleho ea ts'ebetso, bonolo le ho thatafala ha bokaholimo ba terata, ho khomarela ha mokhanni, hammoho le thepa ea mechini le ea 'mele le thepa ea motlakase ea terata ka boeona.

B. E na le ts'ebetso e ntle ea ho thibela malakabe, kahoo lithapo tse koahetsoeng ka PVC li ka fihlela habonolo limaraka tsa ho thibela malakabe tse boletsoeng ke maemo a fapaneng.

C. Mabapi le ho hanyetsa mocheso, ka ho ntlafatsa le ho ntlafatsa mekhoa ea thepa, mefuta e sebelisoang haholo ea ho kenya thepa ka har'a PVC e kenyelletsa haholo-holo mekhahlelo e meraro e latelang:

Ha ho tluoa tabeng ea motlakase o lekantsoeng, hangata o sebelisoa maemong a motlakase o lekantsoeng ho 1000V AC le ka tlase, 'me o ka sebelisoa haholo liindastering tse kang lisebelisoa tsa lapeng, lisebelisoa le limithara, mabone le puisano ea marang-rang.

PVC e boetse e na le mefokolo e meng ea tlhaho e fokotsang ts'ebeliso ea eona:

A. Ka lebaka la chlorine e ngata, e tla ntša mosi o mongata o teteaneng ha e cha, e leng se ka bakang ho bipetsana, sa ama ponahalo, mme sa hlahisa di-carcinogen le kgase ya HCl, sa baka tshenyo e kgolo tikolohong. Ka ntshetsopele ya theknoloji ya tlhahiso ya thepa ya ho thibela ho tjhesa e se nang mosi o tlase, butle-butle ho nkela sebaka sa ho thibela ho tjhesa ha PVC sebaka e se e le mokgwa o ke keng wa qojwa ntshetsopeleng ya dikhoele.

B. Ho thibela mocheso ho tloaelehileng ha PVC ho na le khanyetso e fokolang ho li-acid le alkali, oli e futhumatsang le li-solvent tsa tlhaho. Ho ea ka molao-motheo oa lik'hemik'hale oa ho qhibiliha ho tšoana le, lithapo tsa PVC li kotsing e kholo ea ho senyeha le ho petsoha tikolohong e itseng e boletsoeng. Leha ho le joalo, ka ts'ebetso ea eona e ntle ea ts'ebetso le litšenyehelo tse tlase. Lithapo tsa PVC li ntse li sebelisoa haholo lisebelisoa tsa lapeng, lisebelisoa tsa mabone, lisebelisoa tsa mechini, lisebelisoa le limithara, puisano ea marang-rang, lithapo tsa meaho le masimo a mang.

2. Lithapo le likhoele tsa polyethylene tse hokahaneng ka sefapano

PE e hokahaneng ka sefapano (eo ho tloha mona e tla bitsoaXLPE) ke mofuta oa polyethylene e ka fetohang ho tloha sebopehong sa limolek'hule se otlolohileng ho ea sebopehong sa mahlakore a mararo a mararo tlas'a maemo a itseng tlas'a ts'ebetso ea mahlaseli a matla a phahameng kapa li-cross-linking agents. Ka nako e ts'oanang, e fetoha ho tloha ho thermoplastic ho ea ho polasetiki ea thermosetting e sa qhibiliheng.

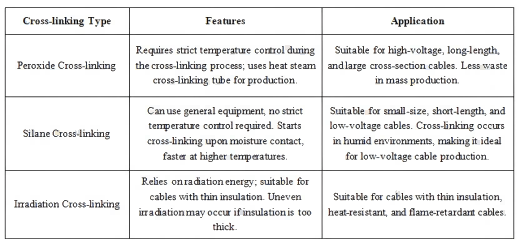

Hona jwale, tshebedisong ya ho kenya terata le ho kenya dikheibole, ho na le mekgwa e meraro ya ho hokahanya:

A. Ho kopanya peroxide: Ho kenyelletsa ho qala ka ho sebedisa resin ya polyethylene hammoho le di-agent tse loketseng tsa ho kopanya le di-antioxidants, ebe ho eketswa dikarolo tse ding ha ho hlokahala ho hlahisa dikarolwana tsa motswako wa polyethylene tse ka hokahanang. Nakong ya tshebetso ya ho ntsha, ho kopanya ho etsahala ka diphaephe tse kopanyang tsa mouoane o chesang.

B. Ho kopanya Silane (ho kopanya metsi a futhumetseng): Ena hape ke mokhoa oa ho kopanya lik'hemik'hale. Mokhoa oa eona o ka sehloohong ke ho kopanya organosiloxane le polyethylene tlas'a maemo a itseng, e leng

'me tekanyo ea ho hokahanya ka kakaretso e ka fihla ho hoo e ka bang 60%.

C. Ho kopanya mahlasedi ka mahlaseli: E sebedisa mahlasedi a matla a phahameng a kang mahlasedi a R, mahlasedi a alpha, le mahlasedi a dielektrone ho kenya tshebetsong diathomo tsa khabone ka hara dimolekhule tse kgolo tsa polyethylene le ho baka ho hokahanya mahlasedi. Mahlasedi a matla a phahameng a sebediswang hangata ka hara dithapo le dithapo ke mahlasedi a dielektrone a hlahiswang ke di-accelerator tsa dielektrone. Kaha ho hokahanya hona ho itshetlehile ka matla a mmele, ke karolo ya ho hokahanya mahlasedi ka matla a mmele.

Mekhoa e meraro e fapaneng ea ho hokahanya e kaholimo e na le litšobotsi le lits'ebetso tse fapaneng:

Ha ho bapisoa le polyethylene ea thermoplastic (PVC), ho kenya thepa ka har'a XLPE ho na le melemo e latelang:

A. E ntlafalitse khanyetso ea ho feto-fetoha ha mocheso, e ntlafalitse thepa ea mechini mochesong o phahameng, 'me e ntlafalitse khanyetso ea ho petsoha ha khatello ea tikoloho le botsofali ba mocheso.

B. E ntlafalitse botsitso ba lik'hemik'hale le khanyetso ea solvent, e fokolitse phallo ea serame, 'me ha e le hantle e bolokile ts'ebetso ea motlakase ea pele. Mocheso oa ts'ebetso oa nako e telele o ka fihla ho 125℃ le 150℃. Terata le thapo ea polyethylene e hokahaneng le sefapano le eona e ntlafatsa khanyetso ea potoloho e khuts'oane, 'me khanyetso ea eona ea mocheso oa nako e khuts'oane e ka fihla ho 250℃, bakeng sa lithapo le lithapo tsa botenya bo tšoanang, bokhoni ba ho jara hona joale ba polyethylene e hokahaneng le sefapano bo boholo haholo.

C. E na le thepa e ntle ea mechine, e sa keneleng metsi le e hanelang mahlaseli, kahoo e sebelisoa haholo masimong a fapaneng. Tse kang: lithapo tsa khokahano ea kahare bakeng sa lisebelisoa tsa motlakase, lithapo tsa motlakase, lithapo tsa mabone, lithapo tsa taolo ea matšoao a motlakase o tlase bakeng sa likoloi, lithapo tsa terene, lithapo le lithapo tsa terene e ka tlas'a lefatše, lithapo tsa tšireletso ea tikoloho bakeng sa merafo, lithapo tsa metsing, lithapo tsa ho beha matla a nyutlelie, lithapo tsa motlakase o phahameng bakeng sa TV, lithapo tsa motlakase o phahameng bakeng sa ho thunya ka X-RAY, le lithapo tsa phetisetso ea motlakase le lithapo, jj.

Lithapo le likhoele tse koahetsoeng ka XLPE li na le melemo e meholo, empa li boetse li na le mathata a mang a tlhaho a fokotsang ts'ebeliso ea tsona:

A. Tshebetso e mpe ea ho khomarela mocheso. Ha ho sebetsoa le ho sebelisoa lithapo tse fetang mocheso oa tsona o lekantsoeng, ho bonolo hore lithapo li khomarele. Maemong a boima, ho ka lebisa tšenyo ea insulation le lipotoloho tse khutšoane.

B. Ho hanyetsa mocheso hantle. Ha mocheso o feta 200℃, ho thibela ho kenngwa ha dithapo ho ba bonolo haholo. Ha di kenngwa ka matla a kantle kapa ho thulana, ho ka etsahala hore dithapo di kgaole mme di kgaole potoloho.

C. Ho thata ho laola phapang ea mebala lipakeng tsa lihlopha. Mathata a kang ho ngoatheha, ho soeufala le ho petsoha ha litlhaku tse hatisitsoeng a ka hlaha nakong ea ts'ebetso.

D. Ho thibela mocheso ka XLPE ka tekanyo ea 150℃ ha ho na halogen ka ho feletseng 'me ho ka feta teko ea ho chesa ea VW-1 ho latela maemo a UL1581, ha ka nako e ts'oanang ho boloka thepa e ntle ea mechini le ea motlakase. Leha ho le joalo, ho ntse ho e-na le litšitiso tse itseng theknolojing ea tlhahiso 'me litšenyehelo li holimo.

3. Lithapo le likhoele tsa rabara tsa silicone

Limolek'hule tsa polymer tsa rabara ea silicone ke meaho ea ketane e entsoeng ka litlamo tsa SI-O (silicon-oxygen). Tlamo ea SI-O ke 443.5KJ/MOL, e leng e phahameng haholo ho feta matla a tlamo ea CC (355KJ/MOL). Lithapo le likhoele tse ngata tsa rabara ea silicone li hlahisoa ka ho ntša metsi a batang le mekhoa ea ho qhibilihisa mocheso o phahameng. Har'a lithapo le likhoele tse fapaneng tsa rabara tsa maiketsetso, ka lebaka la sebopeho sa eona se ikhethang sa limolek'hule, rabara ea silicone e na le ts'ebetso e phahameng ha e bapisoa le lirabara tse ling tse tloaelehileng.

A. E bonolo haholo, e na le ho tenyetseha ho hoholo, ha e na monko ebile ha e na chefo, 'me ha e tšabe mocheso o phahameng 'me e ka mamella serame se matla. Moeli oa ts'ebetso o pakeng tsa -90 le 300℃. Rabara ea silicone e na le ho hanyetsa mocheso ho feta rabara e tloaelehileng. E ka sebelisoa khafetsa ho 200℃ le ka nako e itseng ho 350℃.

B. Ho hanyetsa boemo ba leholimo hantle haholo. Esita le ka mor'a ho pepesehela mahlaseli a ultraviolet nako e telele le maemo a mang a leholimo, litšobotsi tsa eona tsa 'mele li bile le liphetoho tse nyane feela.

C. Rabara ea silicone e na le matla a ho hanyetsa a phahameng haholo 'me khanyetso ea eona e lula e tsitsitse maemong a fapaneng a mocheso le maqhubu.

Ho sa le jwalo, rabara ya silicone e na le kganyetso e babatsehang kgahlanong le ho ntshwa ha corona ka motlakase o phahameng le ho ntshwa ha arc. Dithapo le dithapo tse kwahetsweng ka rabara ya silicone di na le melemo e mengata mme di sebediswa haholo dithapong tsa disebediswa tse nang le motlakase o phahameng bakeng sa dithelevishene, dithapo tse hanelang mocheso o phahameng bakeng sa dionto tsa microwave, dithapo tsa di-induction cooker, dithapo tsa dipitsa tsa kofi, di-lod bakeng sa mabone, disebediswa tsa UV, mabone a halogen, dithapo tsa kgokelo ya kahare bakeng sa dionto le difene, haholoholo lefapheng la disebediswa tse nyane tsa ka tlung.

Leha ho le jwalo, mefokolo e meng ya yona le yona e fokotsa tshebediso ya yona ka bophara. Mohlala:

A. Ho se kgone ho taboha hantle. Nakong ya ho sebetswa kapa ho sebediswa, e kotsing ya ho senyeha ka lebaka la ho hatelloa, ho ngoapa le ho silwa ka matla a kantle, e leng se ka bakang potoloho e kgutshwane. Mokgwa wa ho sireletsa wa hajwale ke ho eketsa lera la faeba ya khalase kapa faeba ya polyester e lohiloeng ka ntle ho silicone insulation. Leha ho le jwalo, nakong ya ho sebetswa, ho ntse ho hlokahala ho qoba dikotsi tse bakwang ke ho hatelloa ka matla a kantle ka hohle kamoo ho ka kgonehang.

B. Moemeli oa vulcanizing o sebelisoang haholo-holo ho bōpeng ha vulcanization ke habeli, peli, 'ne. Moemeli ona oa vulcanizing o na le chlorine. Meemeli ea vulcanizing e se nang halogen ka ho feletseng (joalo ka platinum vulcanizing) e na le litlhoko tse tiileng bakeng sa mocheso oa tikoloho ea tlhahiso 'me e bitsa chelete e ngata. Ka hona, ha ho sebetsoa li-harnesses tsa terata, lintlha tse latelang li lokela ho hlokomeloa: khatello ea lebili la khatello ha ea lokela ho ba holimo haholo. Ho molemo ho sebelisa thepa ea rabara ho thibela ho robeha nakong ea ts'ebetso ea tlhahiso, e leng se ka lebisang ho hanyetsaneng ho fokolang ha khatello.

4. Terata ea rabara ea ethylene propylene diene monomer (EPDM) (XLEPDM) e hokahaneng ka sefapano

Rabara ea ethylene propylene diene monomer (EPDM) e hokahaneng ka sefapano ke terpolymer ea ethylene, propylene le diene e sa kopanngoang, e hokahaneng ka mekhoa ea lik'hemik'hale kapa mahlaseli. Terata e hokahaneng ka sefapano ea rabara ea EPDM e kopanya melemo ea terata e hokahaneng ka polyolefin le terata e tloaelehileng e hokahaneng ka rabara:

A. E bonolo, e tenyetseha, e tenyetseha, ha e khomarele mochesong o phahameng, e hanyetsa botsofali nako e telele, 'me e hanela maemo a leholimo a thata (-60 ho isa ho 125℃).

B. Ho hanyetsa ozone, ho hanyetsa mahlaseli a kotsi a letsatsi, ho hanyetsa ho thibela mocheso ka motlakase, le ho hanyetsa ho bola ha lik'hemik'hale.

C. Khanyetso ea oli le solvent e tšoana le ea ho thibela rabara ea chloroprene e sebelisoang ka kakaretso. E sebetsoa ka lisebelisoa tse tloaelehileng tsa ho ntša metsi a chesang 'me mahlaseli a sebelisoa ho hokahanya, e leng ntho e bonolo ho e sebetsana le eona ebile e theko e tlase. Lithapo tse sireletsang rabara tsa ethylene propylene diene monomer (EPDM) li na le melemo e mengata e boletsoeng ka holimo 'me li sebelisoa haholo masimong a kang li-lead tsa compressor tsa sehatsetsing, li-lead tsa motor tse sa keneleng metsi, li-lead tsa transformer, likhoele tse tsamaeang merafong, ho cheka, likoloi, lisebelisoa tsa bongaka, likepe le lithapo tse akaretsang tsa ka hare tsa lisebelisoa tsa motlakase.

Mathata a maholo a lithapo tsa XLEPDM ke:

K. Jwalo ka dithapo tsa XLPE le PVC, e na le kganyetso e fokolang ya ho taboha.

B. Ho se khomarele hantle le ho ikgomarela ho ama bokgoni ba ho sebetsa ka morao ho moo.

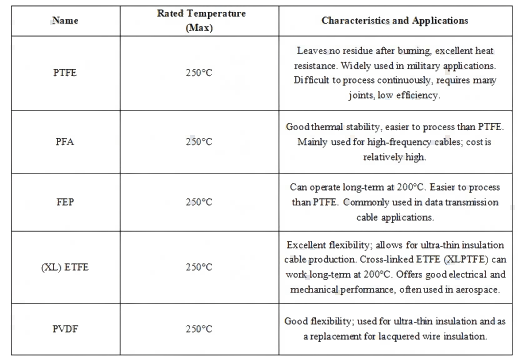

5. Lithapo le likhoele tsa fluoroplastic

Ha ho bapisoa le likhoele tse tloaelehileng tsa polyethylene le polyvinyl chloride, likhoele tsa fluoroplastic li na le likarolo tse latelang tse hlahelletseng:

A. Li-fluoroplastic tse hanelang mocheso o phahameng li na le botsitso bo ikhethang ba mocheso, bo nolofalletsang likhoele tsa fluoroplastic ho ikamahanya le maemo a mocheso o phahameng ho tloha ho likhato tse 150 ho isa ho tse 250 tsa Celsius. Tlas'a maemo a li-conductor tse nang le sebaka se tšoanang sa ho tšela, likhoele tsa fluoroplastic li ka fetisa motlakase o moholo o lumelletsoeng, ka hona li atolosa haholo mefuta ea ts'ebeliso ea mofuta ona oa terata e futhumetseng. Ka lebaka la thepa ena e ikhethang, likhoele tsa fluoroplastic hangata li sebelisoa bakeng sa likhoele tsa kahare le likhoele tsa loto lifofaneng, likepeng, lifonong tsa mocheso o phahameng le lisebelisoa tsa elektroniki.

B. Ho thibela malakabe hantle: Li-fluoroplastic li na le index e phahameng ea oksijene, 'me ha li cha, sebaka sa ho ata ha malakabe se senyenyane, se hlahisa mosi o fokolang. Terata e entsoeng ka eona e loketse lisebelisoa le libaka tse nang le litlhoko tse thata tsa ho thibela malakabe. Mohlala: marang-rang a lik'homphieutha, literene tse tsamaeang ka tlas'a lefatše, likoloi, mehaho e meholo le libaka tse ling tsa sechaba, jj. Hang ha mollo o qhoma, batho ba ka ba le nako ea ho baleha ntle le ho otloa ke mosi o teteaneng, kahoo ba fumana nako ea bohlokoa ea pholoso.

C. Tshebetso e ntle haholo ya motlakase: Ha e bapiswa le polyethylene, di-fluoroplastics di na le dielectric constant e tlase. Ka hona, ha di bapiswa le di-coaxial cables tsa meaho e tshwanang, di-fluoroplastic cables di na le attenuation e nyane mme di loketse haholo phetiso ya matshwao a maqhubu a phahameng. Matsatsing ana, kgafetsa e ntseng e eketseha ya tshebediso ya di-cable e se e le mokgwa. Ho sa le jwalo, ka lebaka la kganyetso e phahameng ya di-fluoroplastics, di atisa ho sebediswa e le terata ya kahare bakeng sa disebediswa tsa phetiso le puisano, di-jumper pakeng tsa di-feeder tsa phetiso ya waelese le di-transmitter, le di-cable tsa video le tsa modumo. Ho feta moo, di-cable tsa fluoroplastic di na le matla a matle a dielectric le kganyetso ya ho thibela ho kwahela, e leng se etsang hore di lokele ho sebediswa e le di-cable tsa taolo bakeng sa disebediswa tsa bohlokwa le dimithara.

D. Thepa e phethahetseng ea mechini le lik'hemik'hale: Li-fluoroplastic li na le matla a phahameng a ho kopanya lik'hemik'hale, botsitso bo phahameng, ha li amehe haholo ke liphetoho tsa mocheso, 'me li na le khanyetso e ntle ea botsofali ba boemo ba leholimo le matla a mechini. 'Me ha e angoe ke li-acid tse fapaneng, li-alkali le li-solvents tsa organic. Ka hona, e loketse libaka tse nang le liphetoho tse kholo tsa tlelaemete le maemo a senyang, joalo ka lik'hemik'hale tsa petrochemical, ho hloekisa oli le taolo ea lisebelisoa tsa seliba sa oli.

E. E nolofatsa dikgokelo tsa ho tjheseletsa Disebedisweng tsa elektroniki, dikgokelo tse ngata di etswa ka ho tjheseletsa. Ka lebaka la ntlha e tlase ya ho qhibiliha ha dipolasetiki tse akaretsang, di atisa ho qhibiliha habonolo dithempereichareng tse phahameng, tse hlokang bokgoni ba ho tjheseletsa. Ho feta moo, dintlha tse ding tsa ho tjheseletsa di hloka nako e itseng ya ho tjheseletsa, e leng lona lebaka leo ka lona dithapo tsa fluoroplastic di ratwang. Jwalo ka ho kenya dithapo ka hare tsa disebediswa tsa puisano le disebediswa tsa elektroniki.

Ehlile, li-fluoroplastics li ntse li na le mathata a mang a fokotsang ts'ebeliso ea tsona:

A. Theko ea thepa e tala e holimo. Hona joale, tlhahiso ea malapeng e ntse e itšetlehile haholo ka thepa e tsoang kantle ho naha (Daikin ea Japane le DuPont ea United States). Leha fluoroplastics ea malapeng e ntlafetse ka potlako lilemong tsa morao tjena, mefuta ea tlhahiso e ntse e le 'ngoe. Ha e bapisoa le thepa e tsoang kantle ho naha, ho ntse ho e-na le sekheo se itseng botsitsong ba mocheso le litšobotsi tse ling tse felletseng tsa thepa.

B. Ha ho bapisoa le thepa e 'ngoe ea ho thibela mocheso, mokhoa oa tlhahiso o thata haholoanyane, bokhoni ba tlhahiso bo tlase, litlhaku tse hatisitsoeng li sekametse ho oa, 'me tahlehelo e kholo, e leng se etsang hore litšenyehelo tsa tlhahiso li be holimo haholo.

Qetellong, ts'ebeliso ea mefuta eohle e boletsoeng ka holimo ea thepa ea ho thibela mocheso, haholo-holo thepa e khethehileng ea ho thibela mocheso e nang le khanyetso ea mocheso e fetang 105℃, e ntse e le nakong ea phetoho Chaena. Ebang ke tlhahiso ea terata kapa ts'ebetso ea terata, ha se feela ts'ebetso e hōlileng tsebong, empa hape le ts'ebetso ea ho utloisisa ka ho utloahalang melemo le mefokolo ea mofuta ona oa terata.

Nako ea poso: Mots'eanong-27-2025