Polyethylene (PE) e sebelisoa haholo hoho kenya le ho thiba likhoele tsa motlakase le likhoele tsa puisanoka lebaka la matla a eona a matle a mechini, ho tiea, ho hanyetsa mocheso, ho thibela mocheso le botsitso ba lik'hemik'hale. Leha ho le joalo, ka lebaka la litšobotsi tsa sebopeho sa PE ka boeona, ho hanyetsa ha eona ho petsoha ha khatello ea tikoloho ho fokola haholo. Bothata bona bo hlahella haholo ha PE e sebelisoa e le sheath e ka ntle ea likhoele tse sirelelitsoeng tse nang le karolo e kholo.

1. Mokhoa oa ho Petsoha ha Selateng sa PE

Ho petsoha ha sheath ea PE ho etsahala haholo maemong a mabeli:

a. Ho Petsoha ha Kgatelelo ya Tikoloho: Sena se bolela ketsahalo eo ho yona sheath e fetang ho petsoha ho tetebelang ho tloha hodima metsi ka lebaka la kgatello e kopaneng kapa ho pepesehela tikoloho kamora ho kenngwa le ho sebediswa ha thapo. Haholo-holo e bakwa ke kgatello ya ka hare ka hara sheath le ho pepesehela metsi a polar nako e telele. Diphuputso tse pharaletseng mabapi le phetoho ya thepa di rarollotse mofuta ona wa ho petsoha haholo.

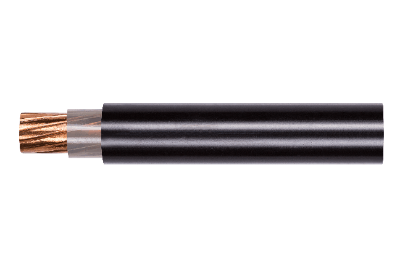

b. Ho Petsoha ha Kgatelelo ya Mekaniki: Sena se etsahala ka lebaka la bofokodi ba sebopeho ka hara thapo kapa mekgwa e sa lokelang ya ho ntsha sheath, e leng se lebisang ho kgatellong e kgolo le ho petsoha ho bakwang ke ho fetoha ha thapo nakong ya ho kenngwa ha thapo. Mofuta ona wa ho petsoha o bonahala haholo ka hara sheath e ka ntle ya thapo e tshepe e nang le thapo e kgolo.

2. Mabaka a ho Petsoha ha Sheath ea PE le Mehato ea Ntlafatso

2.1 Tšusumetso ea CableTheipi ea TšepeSebopeho

Likhoeleng tse nang le bophara bo boholo ba kantle, lera le sirelelitsoeng hangata le entsoe ka li-wrap tsa tšepe tse nang le mekhahlelo e 'meli. Ho latela bophara ba kantle ba thapo, botenya ba thapo ea tšepe boa fapana (0.2mm, 0.5mm, le 0.8mm). Litheipi tsa tšepe tse sirelelitsoeng tse teteaneng li na le ho tiea ho hoholo le polasetiki e fokolang, e leng se fellang ka sebaka se seholo pakeng tsa mekhahlelo e ka holimo le e ka tlase. Nakong ea ho ntša, sena se baka liphapang tse kholo botenya ba sheath pakeng tsa mekhahlelo e ka holimo le e ka tlase ea bokaholimo ba lera le sirelelitsoeng. Libaka tse tšesaane tsa sheath tse mathōkong a thapo ea tšepe e ka ntle li na le khatello e kholo ka ho fetisisa 'me ke libaka tsa mantlha moo ho petsohang nakong e tlang ho etsahalang teng.

Ho fokotsa tšusumetso ea theipi ea tšepe e sirelelitsoeng sekoting se ka ntle, lera la buffering la botenya bo itseng le phutheloa kapa le ntšoa pakeng tsa theipi ea tšepe le sekoting sa PE. Lera lena la buffering le lokela ho ba le teteaneng ka ho lekana, ntle le makukuno kapa matheba. Ho eketsoa ha lera la buffering ho ntlafatsa boreleli pakeng tsa mekhahlelo e 'meli ea theipi ea tšepe, ho netefatsa botenya ba sekoting sa PE bo lekanang, 'me, hammoho le ho honyela ha sekoting sa PE, ho fokotsa khatello ea ka hare.

ONEWORLD e fa basebelisi botenya bo fapaneng bathepa e sirelelitsoeng ka theipi ea tšepe e entsoeng ka galvanizedho fihlela litlhoko tse fapaneng.

2.2 Tšusumetso ea Ts'ebetso ea Tlhahiso ea Lithapo

Mathata a mantlha ka ts'ebetso ea ho ntša likhetla tse kholo tsa kantle tse nang le bophara ba tšepe ke ho pholisa ho sa lekaneng, ho lokisa hlobo ho sa lokelang, le karolelano e feteletseng ea ho otlolla, e leng se fellang ka khatello e feteletseng ea ka hare ka har'a sheath. Likhetla tse kholo, ka lebaka la likhetla tsa tsona tse teteaneng le tse sephara, hangata li tobana le lithibelo boleleleng le bophahamong ba lithapo tsa metsi meleng ea tlhahiso ea ho ntša. Ho pholisa ho tloha ho likhato tse fetang 200 tsa Celsius nakong ea ho ntša ho ea mochesong oa kamore ho baka mathata. Ho pholisa ho sa lekaneng ho lebisa sheath e bonolo haufi le lera la tšireletso, e leng se bakang ho ngoapa holim'a sheath ha thapo e kobehile, qetellong ho fella ka mapetso le ho robeha ho ka bang teng nakong ea ho beoa ha thapo ka lebaka la matla a kantle. Ho feta moo, ho pholisa ho sa lekaneng ho tlatsetsa ho eketseheng ha matla a ka hare a ho kobeha ka mor'a ho kobeha, ho phahamisa kotsi ea ho petsoha ha sheath tlas'a matla a maholo a kantle. Ho netefatsa hore ho pholisa ho lekaneng, ho khothalletsoa ho eketsa bolelele kapa bophahamo ba lithapo tsa metsi. Ho fokotsa lebelo la ho ntša ha ho ntse ho bolokoa polasetiki e nepahetseng ea sheath le ho lumella nako e lekaneng ea ho pholisa nakong ea ho kobeha hoa hlokahala. Ho phaella moo, ho nahana ka polyethylene e le polymer e kristale, mokhoa oa ho pholisa mocheso o arotsoeng ka likarolo, ho tloha ho 70-75°C ho isa ho 50-55°C, 'me qetellong ho ea mochesong oa kamore, ho thusa ho fokotsa khatello ea ka hare nakong ea ts'ebetso ea ho pholisa.

2.3 Tšusumetso ea Radius ea ho Koaela ho Koaela ka Cable

Nakong ea ho kobeha ha thapo, bahlahisi ba khomarela litekanyetso tsa indasteri bakeng sa ho khetha lireele tse loketseng tsa ho isa thepa. Leha ho le joalo, ho amohela bolelele bo bolelele ba ho isa thepa bakeng sa lithapo tse kholo tsa bophara ba kantle ho baka mathata ho khetheng lireele tse loketseng. Ho fihlela bolelele bo boletsoeng ba ho isa thepa, bahlahisi ba bang ba fokotsa bophara ba lireele tsa thapo, e leng se fellang ka mahlaseli a sa lekaneng a ho kobeha bakeng sa thapo. Ho kobeha ho feteletseng ho lebisa ho falleng ha lirafshoa, ho bakang matla a bohlokoa a ho beola sheath. Maemong a boima, li-burrs tsa tšepe e sirelelitsoeng li ka phunya lera la cushion, tsa kenella ka ho toba ka har'a sheath 'me tsa baka mapetso kapa mapetso moeling oa strip ea tšepe. Nakong ea ho beha thapo, matla a ho kobeha le ho hula a lehlakoreng a etsa hore sheath e petsohe pela mapetso ana, haholo-holo bakeng sa lithapo tse haufi le likarolo tse ka hare tsa thapo, e leng se etsang hore li be kotsing ea ho robeha habonolo.

2.4 Tšusumetso ea Tikoloho ea Kaho le ho Kenya Sebakeng

Ho etsa hore kaho ea thapo e be maemong a tloaelehileng, ho eletsoa ho fokotsa lebelo la ho beoa ha thapo, ho qoba khatello e feteletseng ea lehlakore, ho kobeha, matla a ho hula le ho thulana ha bokaholimo, ho netefatsa tikoloho e tsoetseng pele ea kaho. Ka ho khetheha, pele ho kenngoa thapo, lumella thapo hore e phomole ho 50-60°C ho lokolla khatello ea ka hare ho tsoa thapong. Qoba ho pepesehela thapo nako e telele letsatsing le tobileng, kaha mocheso o fapaneng mahlakoreng a fapaneng a thapo o ka lebisa khatellong e kholo, e leng se eketsang kotsi ea ho petsoha ha thapo nakong ea ho beoa ha thapo.

Nako ea poso: Tshitwe-18-2023