Nako e ncha ea indasteri ea likoloi tse ncha tsa matla e jara thomo e habeli ea phetoho ea indasteri le ntlafatso le ts'ireletso ea tikoloho ea sepakapaka, e leng se susumetsang haholo nts'etsopele ea indasteri ea likhoele tsa motlakase o phahameng le lisebelisoa tse ling tse amanang le tsona bakeng sa likoloi tsa motlakase, 'me bahlahisi ba likhoele le mekhatlo ea setifikeiti ba sebelisitse matla a mangata lipatlisisong le nts'etsopele ea likhoele tsa motlakase o phahameng bakeng sa likoloi tsa motlakase. Likhoele tsa motlakase o phahameng bakeng sa likoloi tsa motlakase li na le litlhoko tse phahameng tsa ts'ebetso likarolong tsohle, 'me li lokela ho fihlela maemo a RoHSb, litlhoko tse tloaelehileng tsa sehlopha sa UL94V-0 se thibelang malakabe le ts'ebetso e bonolo. Pampiri ena e hlahisa thepa le theknoloji ea ho lokisa likhoele tsa motlakase o phahameng bakeng sa likoloi tsa motlakase.

1.Thepa ea cable e phahameng ea motlakase

(1) Thepa ea mokhanni oa thapo

Hona jwale, ho na le thepa e mmedi e meholo ya lera la thapo ya motlakase: koporo le aluminium. Dikhamphani tse mmalwa di nahana hore motheo wa aluminium o ka fokotsa haholo ditjeo tsa tsona tsa tlhahiso, ka ho eketsa koporo, tshepe, magnesium, silicon le dielemente tse ding motheong wa thepa e hlwekileng ya aluminium, ka mekgwa e ikgethang jwalo ka ho kopanya le ho annealing, ho ntlafatsa tsamaiso ya motlakase, tshebetso ya ho kobeha le ho hanyetsa ho bola ha thapo, e le ho fihlela ditlhoko tsa bokgoni bo tshwanang ba mojaro, ho fihlella phello e tshwanang le ya di-conductor tsa motheo wa koporo kapa le ho feta. Kahoo, ditjeo tsa tlhahiso di bolokwa haholo. Leha ho le jwalo, dikgwebo tse ngata di ntse di nka koporo e le thepa e ka sehloohong ya lera la thapo ya motlakase, pele ho tsohle, ho hanyetsa koporo ho tlase, mme boholo ba tshebetso ya koporo bo betere ho feta ya aluminium boemong bo tshwanang, jwalo ka bokgoni bo boholo ba ho jara motlakase, tahlehelo e tlase ya motlakase, tshebediso e tlase ya matla le tshepo e matla. Hona jwale, kgetho ya di-conductor ka kakaretso e sebedisa di-conductor tse 6 tse bonolo tsa naha (ho hola ha terata e le nngwe ya koporo e tlameha ho ba ho feta 25%, bophara ba monofilament bo ka tlase ho 0.30) ho netefatsa bonolo le ho tiya ha monofilament ya koporo. Tafole ea 1 e thathamisa maemo a lokelang ho finyelloa bakeng sa thepa ea conductor ea koporo e sebelisoang hangata.

(2) Lisebelisoa tsa ho sireletsa mocheso tsa likhoele

Tikoloho ea ka hare ea likoloi tsa motlakase e rarahane, khethong ea thepa e sireletsang mocheso, ka lehlakoreng le leng, ho netefatsa tšebeliso e sireletsehileng ea lera la ho thibela mocheso, ka lehlakoreng le leng, ka hohle kamoo ho ka khonehang ho khetha ts'ebetso e bonolo le thepa e sebelisoang haholo. Hona joale, thepa e sireletsang mocheso e sebelisoang haholo ke polyvinyl chloride (PVC),polyethylene e hokahaneng ka sefapano (XLPE), rabara ea silicone, elastomer ea thermoplastic (TPE), jj., le thepa ea tsona ea mantlha li bontšitsoe ho Tafole ea 2.

Har'a tsona, PVC e na le loto, empa RoHS Directive e thibela tšebeliso ea loto, mercury, cadmium, hexvalent chromium, polybrominated diphenyl ethers (PBDE) le polybrominated biphenyls (PBB) le lintho tse ling tse kotsi, kahoo lilemong tsa morao tjena PVC e nkeloe sebaka ke XLPE, rabara ea silicone, TPE le lisebelisoa tse ling tse sireletsang tikoloho.

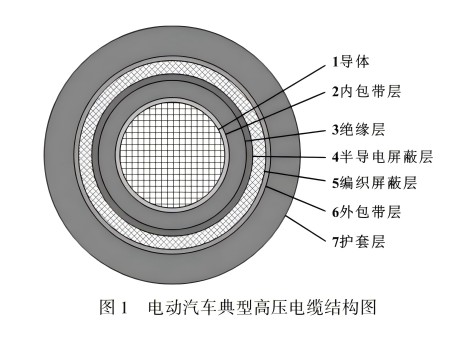

(3) Thepa ea lera la tšireletso ea thapo

Lera la tšireletso le arotsoe likarolo tse peli: lera la tšireletso le tsamaisang motlakase ka halofo le lera la tšireletso le lohiloeng. Boima ba bophahamo ba thepa ea tšireletso e tsamaisang motlakase ka halofo ho 20 ° C le 90 ° C le ka mor'a ho tsofala ke index ea bohlokoa ea botekgeniki ho lekanya thepa ea tšireletso, e leng se khethollang ka tsela e sa tobang bophelo ba tšebeletso ea thapo e nang le motlakase o phahameng. Lisebelisoa tse tloaelehileng tsa tšireletso tse tsamaisang motlakase ka halofo li kenyelletsa rabara ea ethylene-propylene (EPR), polyvinyl chloride (PVC), lepolitheine (PE)thepa e thehiloeng ho yona. Haeba thepa e tala e se na molemo mme boemo ba boleng bo ke ke ba ntlafala ka nako e kgutshwane, ditheo tsa dipatlisiso tsa mahlale le bahlahisi ba thepa ya cable ba tsepamisa maikutlo dipatlisisong tsa theknoloji ya tshebetso le karolelano ya foromo ya thepa ya ho sireletsa, mme ba batla boqapi ka karolelano ya sebopeho sa thepa ya ho sireletsa ho ntlafatsa tshebetso ka kakaretso ya cable.

2.Ts'ebetso ea ho lokisa cable ea motlakase o phahameng

(1) Theknoloji ea khoele ea mokhanni

Ts'ebetso ea motheo ea cable e se e ntlafalitsoe ka nako e telele, kahoo ho boetse ho na le litlhaloso tsa bona tse tloaelehileng indastering le likhoebong. Ts'ebetsong ea ho hula terata, ho latela mokhoa oa ho tlosa terata e le 'ngoe, lisebelisoa tsa ho hula li ka aroloa ka mochini o tlosang likhoele, mochini o tlosang likhoele le mochini o tlosang likhoele/likhoele. Ka lebaka la mocheso o phahameng oa kristale oa mokhanni oa koporo, mocheso oa annealing le nako li telele, ho loketse ho sebelisa lisebelisoa tsa mochini o tlosang likhoele ho etsa monwire e hulang ka ho tsoelang pele le e hulang ka ho tsoelang pele ho ntlafatsa sekhahla sa ho lelefala le ho robeha ha ho hula terata. Hona joale, thapo ea polyethylene e hokahaneng ka sefapano (XLPE) e nkile sebaka sa thapo ea pampiri ea oli ka botlalo lipakeng tsa maemo a motlakase a 1 le 500kV. Ho na le mekhoa e 'meli e tloaelehileng ea ho etsa thapo bakeng sa li-conductor tsa XLPE: ho hatelloa ha selikalikoe le ho sotha terata. Ka lehlakoreng le leng, setsi sa terata se ka qoba mocheso o phahameng le khatello e phahameng phaepheng e hokahaneng ho hatella thepa ea eona ea tšireletso le thepa ea ho thibela ho kenella ka har'a lekhalo la terata e lahlehileng le ho baka tšenyo; Ka lehlakoreng le leng, e ka boela ea thibela ho kenella ha metsi ka lehlakoreng la mokhanni ho netefatsa ts'ebetso e sireletsehileng ea thapo. Motsamaisi oa koporo ka boeona ke sebopeho se kopaneng sa ho khomaretsa likhoele, seo boholo ba sona se hlahisoang ke mochini o tloaelehileng oa ho khomaretsa likhoele tsa foreimi, mochini oa ho khomaretsa likhoele tsa fereko, jj. Ha e bapisoa le ts'ebetso ea ho tiisa selikalikoe, e ka netefatsa sebopeho sa ho khomaretsa likhoele tsa mokhanni.

(2) Ts'ebetso ea tlhahiso ea ho kenya thapo ea XLPE

Bakeng sa tlhahiso ea thapo ea XLPE ea motlakase o phahameng, ho kopanya ho omileng ka mokhoa o otlolohileng (CCV) le ho kopanya ho omileng ka mokhoa o otlolohileng (VCV) ke lits'ebetso tse peli tsa ho theha.

(3) Ts'ebetso ea ho ntša

Pejana, bahlahisi ba dikheibole ba ne ba sebedisa mokgwa wa bobedi wa ho ntsha dikheibole ho hlahisa motheo wa ho kenya dikheibole, mohato wa pele ka nako e le nngwe thebe ya mokhanni wa ho ntsha le lera la ho kenya dikheibole, ebe ba hokahanngwa le ho phunya tereing ya thapo, ba bewa nako e itseng ebe thebe ya ho kenya dikheibole. Nakong ya bo-1970, mokgwa wa ho ntsha dikheibole tse tharo wa 1+2 o ile wa hlaha motheong wa terata e kentsweng dikheibole, o dumella hore thebe ya kahare le ya kantle le ho kenya dikheibole di phethelwe ka mokgwa o le mong. Mokgwa ona o qala ka ho ntsha thebe ya mokhanni, kamora sebaka se sekgutshwane (2~5m), ebe o ntsha thebe ya ho kenya dikheibole le ho kenya dikheibole thebeng ya mokhanni ka nako e le nngwe. Leha ho le jwalo, mekgwa e mmedi ya pele e na le mathata a maholo, kahoo mafelong a bo-1990, bafepedi ba disebediswa tsa tlhahiso ya dikheibole ba ile ba hlahisa mokgwa wa tlhahiso ya ho ntsha dikheibole tse nang le mekhahlelo e meraro, e neng e ntsha thebe ya mokhanni, ho kenya dikheibole le ho kenya dikheibole ka nako e le nngwe. Lilemong tse 'maloa tse fetileng, linaha tsa kantle ho naha le tsona li qalile hlooho e ncha ea moqomo oa extruder le moralo oa poleiti ea letlooeng e kobehileng, ka ho leka-lekanya khatello ea phallo ea sekoti sa hlooho ea sekurufu ho fokotsa pokello ea thepa, ho eketsa nako ea tlhahiso e tsoelang pele, ho nkela phetoho e sa khaotseng ea litlhaloso tsa moralo oa hlooho sebaka le hona ho ka boloka litšenyehelo tsa nako ea ho phomola haholo le ho ntlafatsa ts'ebetso.

3. Qetello

Likoloi tse ncha tsa eneji li na le menyetla e metle ea nts'etsopele le 'maraka o moholo, li hloka letoto la lihlahisoa tsa cable ea motlakase o phahameng tse nang le bokhoni bo phahameng ba mojaro, khanyetso ea mocheso o phahameng, phello ea tšireletso ea motlakase, khanyetso ea ho kobeha, ho tenyetseha, bophelo bo bolelele ba ts'ebetso le ts'ebetso e 'ngoe e ntle ea tlhahiso le ho lula' marakeng. Thepa ea cable ea motlakase ea koloi ea motlakase le ts'ebetso ea eona ea ho lokisa li na le menyetla e meholo ea nts'etsopele. Koloi ea motlakase e ke ke ea ntlafatsa ts'ebetso ea tlhahiso le ho netefatsa ts'ebeliso ea polokeho ntle le cable ea motlakase o phahameng.

Nako ea poso: Phato-23-2024