Lihlahisoa

Gel ea ho Tlatsa Fiber ea Optical - Gel ea Fiber

Gel ea ho Tlatsa Fiber ea Optical - Gel ea Fiber

Selelekela sa Sehlahisoa

Gel ea ho tlatsa faeba ea optical ke peista e tšoeu e bonaletsang, e nang le oli ea motheo, filler e sa tloaelehang, thickener, regulator, antioxidant, jj., e futhumatsoang ka tekanyo e itseng 'me e kopantsoe ka har'a kettle ea karabelo, ebe e sila, e pholisa le ho ntša khase.

Bakeng sa thapo ya optical ya kantle, e le ho thibela metsi le mongobo ho fokotsa matla a faeba ya optical le ho eketsa tahlehelo ya phetisetso e amang boleng ba puisano, ho hlokahala ho tlatsa tube e hlephileng ya thapo ya optical ka thepa e thibelang metsi jwalo ka gel ya ho tlatsa faeba ya optical ho fihlella phello ya ho kwala le ho thibela metsi, ho thibela kgatello ya maikutlo, le ho sireletsa faeba ya optical. Boleng ba gel ya ho tlatsa faeba ya optical bo ama ka ho toba botsitso ba tshebetso ya phetisetso ya faeba ya optical le bophelo ba thapo ya optical.

Re ka fana ka mefuta e fapaneng ea gel ea ho tlatsa faeba, haholo-holo ho kenyeletsoa gel e tloaelehileng ea ho tlatsa faeba ea optical (e loketseng ho tlatsa ho potoloha likhoele tsa optical ka har'a tube e tloaelehileng e hlephileng), gel ea ho tlatsa bakeng sa liribone tsa faeba ea optical (e loketseng ho tlatsa ho potoloha liribone tsa faeba ea optical), gel ea faeba ea optical e monyang haeterojene (e loketseng ho tlatsa ho potoloha gell ea faeba ea optical ka har'a tube ea tšepe) jj.

Jel ea faeba ea optical e fanoeng ke k'hamphani ea rona e na le botsitso bo botle ba lik'hemik'hale, botsitso ba mocheso, e thibelang metsi, thixotropy, phetoho e fokolang ea haeterojene, lipululana tse fokolang, e lumellana hantle le lifaeba tsa optical le lipeipi tse hlephileng, 'me ha e na chefo ebile ha e kotsi ho batho.

Kopo

E sebelisoa haholo bakeng sa ho tlatsa lipeipi tse hlephileng tsa polasetiki le lipeipi tse hlephileng tsa tšepe tsa cable ea optical e hlephileng ea kantle, cable ea optical ea OPGW le lihlahisoa tse ling.

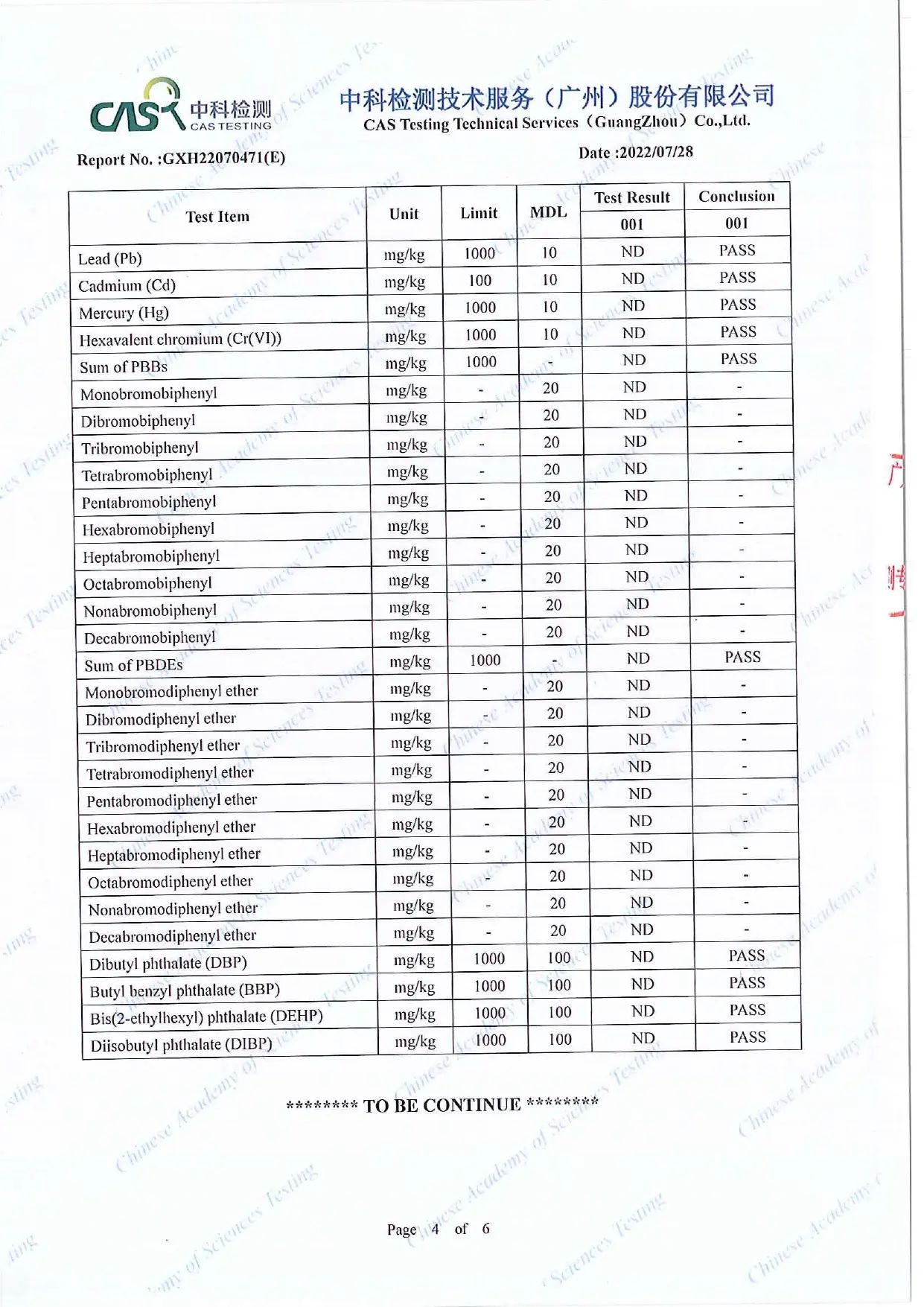

| Tjhe. | Ntho | Yuniti | Index |

| 1 | Ponahalo | / | E ts'oanang, ha ho litšila |

| 2 | Sebaka sa ho theoha | ℃ | ≥150 |

| 3 | Botenya (20℃) | g/cm3 | 0.84±0.03 |

| 4 | Ho kenella ha khoune ka 25℃ - 40℃ | 1/10mm | 600±30 |

| ≥230 | |||

| 5 | Botsitso ba 'mala (130℃, 120h) | / | ≤2.5 |

| 6 | Nako ea ho kenya oksijene (10℃ / mets, 190℃) | motsotso | ≥30 |

| 7 | Sebaka sa ho benya | ℃ | >200 |

| 8 | Phetoho ea haedrojene (80℃, lihora tse 24) | μl/g | ≤0.03 |

| 9 | Ho fufuleloa ha oli (80℃, lihora tse 24) | % | ≤0.5 |

| 10 | Bokgoni ba mouoane (80℃, lihora tse 24) | % | ≤0.5 |

| 11 | Khanyetso ea metsi (23℃, 7×24h) | / | Ho se qhaqholle |

| 12 | Boleng ba asiti | mgK0H/g | ≤0.3 |

| 13 | Metsi a mangata | % | ≤0.01 |

| 14 | Ho tsikinyeha (25℃, D=50s)-1) | mPa.s | 2000±1000 |

| 15 | Ho lumellana: A, ka faeba ea optical, faeba ea optical liribone tse koahelang (85℃ ± 1℃, 30×24h) B, ka liphaephe tse hlephileng tse bonahalang (85℃±1℃,30×24h) phapang ea matla a ho tsikinyeha Ho roba bolelele phapang ea boima | % | Ha ho na ho fifala, ho falla, ho arohana, ho petsoha Matla a ho lokolla a phahameng ka ho fetisisa: 1.0N ~ 8.9N Boleng bo tloaelehileng:1.0N~5.0N Ha ho na ho qhaqha, ho petsoha ≤25 ≤30 ≤3 |

| 16 | E senyang (80℃, 14×24h) ka koporo, aluminium, tšepe | / | Ha ho lintlha tsa ts'enyeho |

| Malebela: a loketse ho tlatsa thapo e nyane kapa thapo e nyane e lokolohileng ya fiber optic tube. | |||

Li-parameter tsa Tekheniki

| Gel ea ho tlatsa fiber ea optical ea mofuta oa OW-210 bakeng sa tube e tloaelehileng e hlephileng | |||

| Tjhe. | Ntho | Yuniti | Index |

| 1 | Ponahalo | / | E ts'oanang, ha ho litšila |

| 2 | Sebaka sa ho theoha | ℃ | ≥200 |

| 3 | Botenya (20℃) | g/cm3 | 0.83±0.03 |

| 4 | Ho kenella ha khoune 25℃ -40℃ | 1/10mm | 435±30 ≥230 |

| 5 | Botsitso ba 'mala (130℃, 120h) | / | ≤2.5 |

| 6 | Nako ea tlhahiso ea oxidation (10℃/min, 190℃) | motsotso | ≥30 |

| 7 | Sebaka sa ho benya | ℃ | >200 |

| 8 | Phetoho ea haedrojene (80℃, lihora tse 24) | μl/g | ≤0.03 |

| 9 | Ho fufuleloa ha oli (80℃, lihora tse 24) | % | ≤0.5 |

| 10 | Bokgoni ba mouoane (80℃, lihora tse 24) | % | ≤0.5 |

| 11 | Khanyetso ea metsi (23℃, 7×24h) | / | Ho se qhaqholle |

| 12 | Boleng ba asiti | mgK0H/g | ≤0.3 |

| 13 | Metsi a mangata | % | ≤0.01 |

| 14 | Ho tsikinyeha (25℃,D=50s-1) | mPa.s | 4600±1000 |

| 15 | Sebeletsana: A, ka faeba ea optical, ribbons tsa faeba ea optical tse nang le thepa ea ho roala (85℃ ± 1℃, 30×24h)B, ka liphaephe tse hlephileng tse bonahalang (85℃±1℃,30×24h) phapang ea matla a ho tsikinyeha Ho roba bolelele phapang ea boima | % % % | Ha ho na ho fifala, ho falla, ho arohana, ho petsoha Matla a ho lokolla a phahameng ka ho fetisisa: 1.0N ~ 8.9N Boleng bo tloaelehileng:1.0N~5.0N Ha ho na ho qhekelloa, ho petsoha ≤25 ≤30 ≤3 |

| 16 | E senyang (80℃, 14×24h) ka koporo, aluminium, tšepe | / | Ha ho lintlha tsa ts'enyeho |

| Malebela: a loketse ho tlatswa ka phaephe e tloaelehileng e lokolohileng. | |||

| Gel ea ho tlatsa fiber ea micro optical ea mofuta oa OW-220 | |||

| Tjhe. | Ntho | Yuniti | Liparamente |

| 1 | Ponahalo | / | E ts'oanang, ha ho litšila |

| 2 | Sebaka sa ho theoha | ℃ | ≥150 |

| 3 | Botenya (20℃) | g/cm3 | 0.84±0.03 |

| 4 | Ho kenella ha khoune (25℃ -40℃) | 1/10mm | 600±30 |

| ≥230 | |||

| 5 | Botsitso ba 'mala (130℃, 120h) | / | ≤2.5 |

| 6 | Nako ea tlhahiso ea oxidation (10℃/metsotso, 190℃) | motsotso | ≥30 |

| 7 | Sebaka sa ho benya | ℃ | >200 |

| 8 | Phetoho ea haedrojene (80℃, lihora tse 24) | μl/g | ≤0.03 |

| 9 | Ho fufuleloa ha oli (80℃, lihora tse 24) | % | ≤0.5 |

| 10 | Bokgoni ba mouoane (80℃, lihora tse 24) | % | ≤0.5 |

| 11 | Khanyetso ea metsi (23℃, 7×24h) | / | Ho se qhaqholle |

| 12 | Boleng ba asiti | mgK0H/g | ≤0.3 |

| 13 | Metsi a mangata | % | ≤0.01 |

| 14 | Ho thibana (25℃,D=50s)-1) | mPa.s | 2000±1000 |

| 15 | Ho sebeletsana: A, ka faeba ea optical, ribone ea optical faeba e koahelang thepa (85℃ ± 1℃, 30×24h) B, ka liphaephe tse hlephileng tse bonahalang (85℃ ± 1℃, 30×24h) phetoho ea matla a ho teneha Ho roba bolelele | % | Ha ho na ho fifala, ho falla, ho arohana, ho petsoha |

| phapang ea boima | % | Matla a ho lokolla a phahameng ka ho fetisisa: 1.0N ~ 8.9N | |

| % | Boleng bo tloaelehileng:1.0N~5.0N | ||

| Ha ho na ho qhaqha, ho petsoha | |||

| ≤25 | |||

| ≤30 | |||

| ≤3 | |||

| 16 | E senyang (80℃, 14×24h) ka koporo, aluminium, tšepe | / | Ha ho lintlha tsa ts'enyeho |

| Malebela: a loketse ho tlatsa thapo e nyane kapa thapo e nyane e lokolohileng ya fiber gel optic cable. | |||

| Gel ea ho tlatsa fiber ea optical ea mofuta oa OW-230 | |||

| Tjhe. | Ntho | Yuniti | Liparamente |

| 1 | Ponahalo | / | E ts'oanang, ha ho litšila |

| 2 | Sebaka sa ho theoha | ℃ | ≥200 |

| 3 | Botenya (20℃) | g/cm3 | 0.84±0.03 |

| 4 | Ho kenella ha khoune 25℃ -40℃ | 1/10mm | 400±30 |

| ≥220 | |||

| 5 | Botsitso ba 'mala (130℃, 120h) | / | ≤2.5 |

| 6 | Nako ea ho kenya oksijene (10℃ / mets, 190℃) | motsotso | ≥30 |

| 7 | Sebaka sa ho benya | ℃ | >200 |

| 8 | Phetoho ea haedrojene (80℃, lihora tse 24) | μl/g | ≤0.03 |

| 9 | Ho fufuleloa ha oli (80℃, lihora tse 24) | % | ≤0.5 |

| 10 | Bokgoni ba mouoane (80℃, lihora tse 24) | % | ≤0.5 |

| 11 | Khanyetso ea metsi (23℃, 7×24h) | / | Ho se qhaqholle |

| 12 | Boleng ba asiti | mgK0H/g | ≤0.3 |

| 13 | Metsi a mangata | % | ≤0.01 |

| 14 | Ho tsikinyeha (25℃, D=50s)-1) | mPa.s | 8000±2000 |

| 15 | Ho lumellana: A, ka faeba ea optical, faeba ea optical thepa ea ho roala liribone (85℃±1℃,30×24h) B, ka liphaephe tse hlephileng tse bonahalang (85℃±1℃,30×24h) phapang ea matla a ho tsikinyeha Ho roba bolelele phapang ea boima | % % % % % % % | Ha ho na ho fifala, ho falla, ho arohana, ho petsoha Matla a ho lokolla a phahameng ka ho fetisisa: 1.0N ~ 8.9N Boleng bo tloaelehileng:1.0N~5.0N Ha ho na ho qhaqha, ho petsoha ≤25 ≤30 ≤3 |

| 16 | E senyang (80℃, 14×24h) | / | Ha ho lintlha tsa ts'enyeho |

| ka koporo, aluminium, tšepe | |||

| Malebela: a loketse ho tlatswa ka phaephe e tloaelehileng e lokolohileng. | |||

Sephutheloana

Gel ea ho tlatsa fiber ea optical e fumaneha ka mefuta e 'meli ea liphutheloana.

1) 170kg/moropa

2) Tanka ea 800kg/IBC

Polokelo

1) Sehlahisoa se lokela ho bolokoa ka tlung e hloekileng, e hloekileng, e omileng le e nang le moea o kenang.

2) Sehlahisoa se lokela ho bolokoa hole le mehloli ea mocheso, ha sea lokela ho beoa hammoho le lihlahisoa tse tukang 'me ha sea lokela ho ba haufi le mehloli ea mollo.

3) Sehlahisoa se lokela ho qoba khanya ea letsatsi le pula.

4) Sehlahisoa se lokela ho pakoa ka botlalo ho qoba mongobo le tšilafalo.

5) Nako ea polokelo ea sehlahisoa mochesong o tloaelehileng ke lilemo tse 3 ho tloha ka letsatsi la tlhahiso.

Setifikeiti

MELAO EA MAHALA EA SAMPLE

LEFATŠE LE LE LENG LE Ikemiseditse ho Fana ka Litšebeletso tsa Terata le Lithapo tsa Boleng bo Holimo tse Tsoelang Pele le Litšebeletso tsa Botekgeniki tsa Sehlopha sa Pele

O ka Kopa Sampole ea Mahala ea Sehlahisoa Seo U se Thahasellang, e leng se bolelang hore o ikemiselitse ho sebelisa sehlahisoa sa rona bakeng sa tlhahiso.

Re Sebelisa Lintlha tsa Teko tseo U Ikemiselitseng ho li Fana ka Maikutlo le ho li Abelana e le Netefatso ea Litšobotsi le Boleng ba Sehlahisoa, Ebe re re Thusa ho Theha Sistimi e Felletseng ea Taolo ea Boleng ho Ntlafatsa Tšepo le Morero oa Theko oa Bareki, Kahoo Ka kopo Kholiseha

O ka Tlatsa Foromo e ka ho le letona la ho kopa sampole ya mahala

Litaelo tsa Kopo

1. Moreki o na le Ak'haonte ea ho Romela thepa ka potlako ea Machabeng eo a e lefang ka boithatelo (Thepa e ka Khutlisoa ka Odara)

2. Setheo se le seng se ka etsa kopo bakeng sa sampole e le 'ngoe feela ea mahala ea sehlahisoa se le seng, 'me setheo se le seng se ka etsa kopo bakeng sa mehlala e fihlang ho e mehlano ea lihlahisoa tse fapaneng mahala ka hare ho selemo se le seng.

3. Sampole ke ea Bareki ba Feme ea Lithapo le Likhoele Feela, 'me ke ea Basebetsi ba Laboratori feela bakeng sa Teko ea Tlhahiso kapa Lipatlisiso

SEPHUTHELANA SA MEHLALA

FOROMO EA KOPO EA MOHALA EA SAMPLE

Ka kopo kenya Litlhaloso tse Hlokahalang tsa Sampole, kapa u hlalose ka bokhutšoanyane Litlhoko tsa Morero, Re tla U Khothaletsa Mehlala

Kamora ho fana ka foromo, tlhahisoleseling eo u e tlatsang e ka fetisetsoa ho ONE WORLD hore e sebetsoe haholoanyane ho fumana litlhaloso tsa sehlahisoa le tlhahisoleseling ea aterese le uena. 'Me e ka boela ea ikopanya le uena ka mohala. Ka kopo bala ronaleano la lekunutuBakeng sa lintlha tse ling.